Introduction: Crawl space vapor barriers play a critical role in protecting homes from moisture-related issues, ensuring a healthy and energy-efficient living environment. As a crawl space installer, understanding the differences between various thickness options, such as 6 mil, 10 mil, and 20 mil, is essential for educating your clients and making informed decisions for specific crawl space conditions. In this blog, we delve into the characteristics, applications, and pros and cons of each vapor barrier thickness to help you guide your clients effectively.

Classifications of Crawl Space Vapor Retarders

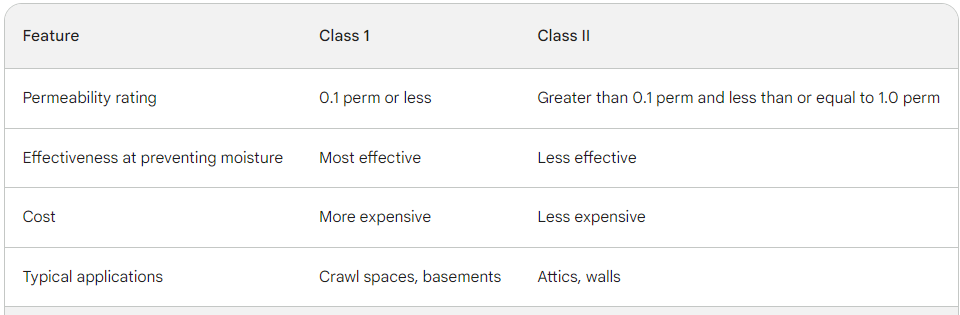

As a homeowner, choosing just any liner for your crawl space may not offer the optimal protection and longevity you seek. Understanding the vapor barrier rating classes is crucial in making an informed decision.

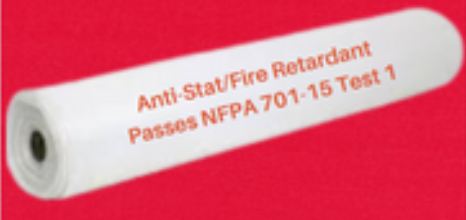

Class 1 vapor barriers are more effective in preventing moisture intrusion, while Class 2 provides a moderate level of protection. However, the ASTM E-1745 standard goes beyond these classifications, ensuring rigorous testing for puncture resistance, tensile strength, and durability. By selecting a vapor barrier that complies with ASTM E-1745, you can be confident in its superior performance, shielding your home from potential mold growth, foundation damage, and energy loss. Investing in a quality vapor barrier with the right rating and ASTM certification ensures a healthier, more resilient crawl space environment, ultimately contributing to the overall well-being and value of your home.

The Permeance of Vapor Retarders

Permeance is a crucial factor to consider when evaluating the effectiveness of a crawl space vapor barrier.

It refers to the measure of how easily moisture can pass through the material.

A lower permeance value indicates that the vapor barrier is more resistant to moisture transmission, making it more effective in preventing water vapor from infiltrating the crawl space. This property is directly related to the vapor barrier rating classes, where Class 1 vapor barriers typically have a lower permeance compared to Class 2.

When homeowners choose a vapor barrier with lower permeance (Class 1), it significantly reduces the chances of moisture seeping into the crawl space. This, in turn, helps prevent mold growth, wood rot, and potential damage to the home's foundation. Additionally, a vapor barrier with lower permeance enhances the crawl space's energy efficiency by reducing the movement of moisture-laden air, resulting in reduced energy consumption and lower utility bills. Ensuring the crawl space vapor barrier meets ASTM E-1745 standards and has an appropriate permeance value is essential in creating a healthy and protected environment for your home.

- 6 Mil Crawl Space Vapor Barrier:

- Application: Suitable for moderately damp crawl spaces with minimal water intrusion or humidity concerns.

- Pros:

- Cost-Effective: 6 mil barriers are generally more budget-friendly, making them an attractive option for clients seeking an economical solution.

- Ease of Installation: Their thinner and more lightweight nature allows for easier handling and installation.

- Versatility: Ideal for use in regions with milder climates or crawl spaces with low moisture issues.

- Cons:

- Durability: While effective in moderate conditions, 6 mil barriers may be more susceptible to punctures and tears in harsher environments.

- 10 Mil Crawl Space Vapor Barrier:

- Application: Recommended for crawl spaces with moderate to high moisture levels or those experiencing occasional water seepage.

- Pros:

- Enhanced Protection: The thicker barrier provides better resistance to tears and punctures, offering superior protection against moisture intrusion.

- Versatility: Suitable for a wide range of crawl space conditions, making it a popular choice among homeowners and contractors.

- Longevity: 10 mil barriers generally have a longer lifespan compared to 6 mil options, ensuring prolonged effectiveness.

- Cons:

- Cost: Slightly more expensive than 6 mil barriers, but the added benefits may outweigh the initial investment.

- 20 Mil Crawl Space Vapor Barrier:

- Application: Best suited for crawl spaces facing severe moisture problems, high water table areas, or frequent flooding occurrences.

- Pros:

- Maximum Protection: With the thickest option available, 20 mil barriers offer unparalleled protection against water intrusion and damage.

- Extreme Durability: Highly resistant to tears, punctures, and abrasions, providing a robust and long-lasting moisture barrier.

- Ideal for Extreme Climates: Perfect for areas with harsh weather conditions and heavy rainfall, where moisture control is paramount.

- Cons:

- Cost: The most expensive of the three options, but crucial for crawl spaces facing extreme moisture challenges.

Additional Tips for Clients:

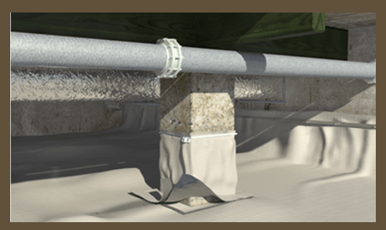

- Sealing: Regardless of the thickness chosen, proper sealing and overlapping of seams are vital for an effective vapor barrier. Ensure that all gaps and joints are appropriately sealed to maintain a continuous barrier.

- Professional Installation: Advise clients to seek professional installation to ensure the vapor barrier is correctly placed and secured for optimal performance.

- Regular Inspections: Remind clients to conduct periodic inspections to detect any signs of damage or wear on the vapor barrier. Prompt repairs or replacements will prevent moisture-related issues.

Conclusion: Choosing the right crawl space vapor barrier thickness depends on the specific conditions and moisture levels in the crawl space. By understanding the characteristics and applications of 6 mil, 10 mil, and 20 mil barriers, you can educate your clients effectively, helping them make informed decisions to safeguard their homes from moisture-related problems and enjoy a healthier living environment for years to come.