Do you know the difference between polyethylene sheeting , poly film and/or plastic sheeting? Of course you do- Polyethylene sheeting is another name for poly film, plastic sheeting, poly liner, "visqueen", plastic film, containment plastic, vapor barrier, geomembrane, green house plastic, and plastic film. Polyethylene or polythene is the most common plastic. As of 2017, over 100 million tons of polyethylene resins are produced annually, accounting for 34% of the total plastics market. Its primary use is in packaging(plastic bags, plastic films, geomembranes, containers including bottles, etc.). Many kinds of polyethylene are known, with most having the chemical formula (C2H4)n.

There are a variety of names that boil down to the main component polyethylene.

Let's take a look at some of the varying product terms and their functions all that are made from polyethylene.

Heavy Duty Plastic Sheeting

What do we mean when we say, "Heavy Duty Plastic Sheeting" or heavy duty poly sheeting? The dictionary defines "heavy duty" as, "made to withstand hard use or wear" and "made to withstand great strain or use". When Global Plastic Sheeting refers to "heavy duty plastic sheeting", we are referring to a plastic sheeting product that is made to withstand hard use or great strain based on the application the plastic sheeting was designed for. Therein lies the difference. A plastic liner is not heavy duty in every application it is presented with. A liner/ film is heavy duty when the plastic was engineered specifically for an application and the film is capable of doing the job it was designed for. It will stay strong, and protect what it was employed to protect.

Another liner/ film that falls into the category of "heavy duty plastic" is a liner called, HDPE. HDPE stands for high density polyethylene. This plastic which is also called a "geomembrane" is engineered with a specially formulated polyethylene resin. It contains approximately 97.5% polyethylene, 2.5% carbon black and trace amounts of antioxidants and heat stabilizers; no other additives, fillers or extenders are used. What you get is a film that has excellent chemical resistance, very low permeability- high tensile strength and more. This liner stands up to UV radiation and can survive outside in harsh conditions. Now that is heavy duty!

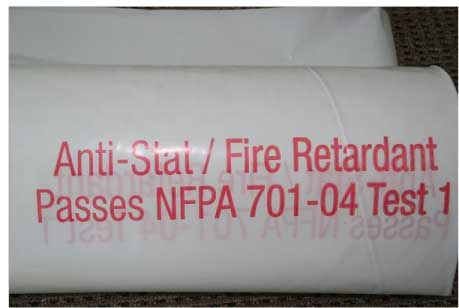

Containment plastic must be heavy duty as well to do its job correctly. What is contaiment plastic? It is plastic that is used to cover the object that needs covering. Take scaffolding. You have seen where it is covered in plastic- that is a specialty plastic called heat shrink wrap. This engineered plastic is made to shrink when heat is applied to tightly cover the building, boat, or object it is protecting. Pictured below is the Mars Rover protected by our specialty heat shrink wrap called, GPS Anti-stiati Fire Retardant Heat Shrink Wrap.

Greenhouse covers- are they also made from polyethylene plastic YES! Can greenhouse plastic be heavy duty? Absolutely. Take SolaWrap greenhouse covering film. This bubble wrap looking plastic will last 10 years in the harshest of environment. It is made to withstand heavy snow loads, high winds, sun, heat, rain- you name it...and it won't yellow or degrade. Other greenhouse covers made from 6 mil polyethylene will only last a few year. And while they will get the job done for a time period, they are not as heavy duty as Solawrap.

Polyethylene sheeting under concrete slab

Under-slab vapor retarders play a very important role in retarding moisture from coming up through the concrete and into the structure. Today most experts feel very strongly that engineered films designed specifically for use as vapor retarders should be used as vapor retarders. These products are made from 100% virgin resins, and have excellent quality control. Most are tested to a standard called the ASTM E1745, which is the standard for vapor retarders in contact with soil or granular fill used under concrete slabs. These materials are engineered not to decay in this type of application, whereas most construction grade poly will begin breaking down almost immediately and will have lost most of its structural integrity within 2 years. How many times have you dug up plastic sheeting in your life that is just destroyed from being buried in the ground? I know this is a bit off subject here, but the principles are even more important when dealing with vapor retarders for hardwood flooring, which is considered a critical application for vapor retarders.

Vapor Retarders for under the home or in the crawl space

Vapor retarders for the most part are made from polyethylene. They too area form of plastic sheeting. It makes some difference what part of the country you are in, what kinds of humidity levels are common in your region, whether or not your home has a good quality vapor retarder under the slab, basement, or in the crawl space. If you already have an excellent vapor retarder, then the one you use under your hardwood floor is far less critical. If you are putting a hardwood floor over a damp crawlspace, and use a poor quality vapor retarder, you are asking for a lot of problems with the hardwood flooring, and will likely suffer problems with buckling, warping, noisy flooring, lots of expansion and contraction, and often finish problems, just to name a few.

Should you be in an area where Radon is prevalent, or methane, then the use of a barrier with capabilities to retard these gasses becomes important also. Again these films are engineered to have a very tight cell structure capable of keeping these very small molecules from passing right through the membrane. These gasses, and to a very large extent water vapor pass quite easily through the cellular structure of common construction grade polyethylene (aka Visqueen).

Shelters or Temporary Protection

When hurricanes strike or disasters ensue, its plastic sheeting that is often used to create temporary shelters. Often string reinforced plastic is used because it is stronger and will hold up to wind.

Coverings for Outdoor Equipment, Wood Piles, Furniture

String Reinforced plastic sheeting is commonly used as well as non-reinforced plastic to make covers for a variety of items. Grommets and hems can be added to the plastic so it can be held down in place.

Waterproofing Ponds, Lakes, Canals with a poly liner

Liners for ponds, lakes and canals use a variety of plastic sheeting called, High Density Polyethylene or HDPE to line their basins. This virgin poly will hold up to the sun and elements.

Recreational Uses such as Ice Skating Rinks, Slip and Slides

The beauty of plastic sheeting is it can be engineered for specific uses. With the addition of special additives, plastic sheeting can work long and hard for the application it was designed for. Ice skating rinks and slip and slides are an example of this. Very large or long rolls of plastic can be ordered from a manufacturer to serve these purposes.

Closing Off Rooms for Remodeling

With the help of an amazing product called ZipWall which will hold plastic sheeting up to the ceiling- you can close off a room where work is being done. This is especially great if dust is flying around from workman activities.

Abatement work for Lead Paint

Lead paint abatement is a big deal. It is very important that lead paint that is being scrapped off a surface does not contaminate other rooms in the house. This is a great place to use plastic sheeting. Anti-static fire retardant plastic is a great choice for this application because the lead dust won't stick to the plastic sheeting. It can be swept up and removed.

Protecting flooring, carpeting, counters, Tubs

There are full lines of plastic that have adhesive on one side so they can stick to the surface they are protecting! Each type (Carpet Plastic, Tile Plastic, Countertop Plastic, etc) have specially formulated adhesive so it sticks just right to that surface. For example, you need a stronger adhesive to stick the plastic to carpeting than you do for plastic being applied to counter. Self-adhesive plastics are great for protecting surfaces from dogs, children's activities, adult parties and more!

Aquaponic lines made from polyethylene

Today there is a specialized type of plastic sheeting that has been created especially for aquaponics. It is called Ultra FGC. Ultra FGC is a food grade compliant liner that was engineered to be not only better for the environment, but better for your business. When we speak of the environment we mean minimizing the raw material usage- thus leaving a smaller environmental footprint. It's better for your business because we reduced the weight of the liner while increasing the capabilities and strength of the plastic.

Plastic sheeting is a polyethylene film that comes in many different colors and thicknesses. It also comes in a variety of grades or qualities.

Grades of Plastic Sheeting

"Virgin Polyethylene" is the highest form of plastic sheeting today. This varies wildly from Visqueen. Visqueen has become one of the generic names for plastic sheeting, just as Kleenex has become the generic name for tissue. When someone asks for Visqueen, they are referring to a lesser grade of plastic sheeting. The plastic sheeting known as Visqueen has become a generic name for Construction and Agricultural Grade Polyethylene sheeting (C&A film). C&A film contains up to 25% post consumer recycled content, and is made from the least expensive resins available at any given time. While it is excellent for use in many projects, it is not ideal for any use that requires sustained strength such as a tarp or for use as a vapor/moisture barrier or retarder. People will often do a search for "visqueen vapor retarder", or fire retardant visqueen" when they may be looking for an engineered plastic. An engineered plastic is one that is intentionally designed to meet certain measurable criteria to insure its suitability for the job it is intended for.

Thickness/ Gauge

The thickness of polyethylene is measured in mils, which equals one-thousandth of an inch, or 0.001 inch. Many of the local hardware or box stores will carry very light duty plastic sheeting that could be 1 to 2 mils thick. Depending on the application will dictate how thick the plastic needs to be. 6 mil is a very common thickness for plastic sheeting- but it can go all the way up to 100 mil! Some refer to the thickness of plastic as "gauge"- but a more precise term is "mil". Plastic wrap, typically sold on rolls in boxes with a cutting edge, clings to many smooth surfaces and can thus remain tight over the opening of a container without adhesive or other devices. Common plastic wrap is roughly 0.5 mils, or 12.5 µm, thick. Please note that the term "gauge" generally refers to the thickness of metal.

The Price of Plastic Sheeting- Why does the prices go up and down?

Polyethylene comes from petroleum oil which vacillates in price.Why are some rolls of plastic more expensive than others? Is there really a big difference between them? Why is one 6 mil roll cheaper than another? As a consumer should you care or just buy the best priced roll?

Tarps, Drop Cloths and Plastic Sheeting

Have you noticed that rolls of plastic that are boxed and sold at big box stores such as Home Depot or Lowe's are better priced than rolls that state "virgin polyethylene"? It's all about the quality of the plastic that is used to make the roll. Inexpensive rolls of plastic may be made from reground scraps. It's referred to in the industry as "regrind". This plastic may have debris churned in which weakens the plastic. This inexpensive plastic does a great job protecting/ covering things where the long term is not important. Tarps, drop cloths and short term covers will do just fine with this film as long as there isn't too much stress put on the plastic.

If however this same 6 mil plastic is being used as a vapor barrier in your basement- now that is a problem. Once the plastic is laid and cement goes over it, what happens to the plastic cannot be seen. It is covered up. What is happening to that plastic is its decomposition over time. That sense of security that you had just may be a false sense of security. This is why reputable crawl space companies consider the following things:

- How rocky is the soil which will be covered with plastic?

- Will there be concrete on top of the plastic, or will it just be bare plastic in the crawl space?

- Will people be storing items in the crawl space and walking on the plastic?

- Is there radon in the area?

All of these factors will determine how thick a crawl space liner should be used plus selecting a vapor barrier that is made from virgin resins and passes tests that prove the plastic will hold up over time. These tests performed on the plastic by a testing lab document the strength of the plastic liner. Suddenly that 6 mil liner from the big box store is not such a good deal when your family's home is involved. Just like a family 4 wheel drive may be suitable for little off road jaunts, that same vehicle may not be suitable for tough terrain that a Hummer is designed for.

If the application is important, select a liner/ plastic sheeting roll that is designed for the job it will perform. Global Plastic Sheeting has very intentional films to do specific jobs accordingly.

Is Plastic Sheeting Bad For The Environment?

Polyethylene can be recycled. It it is out in the sun it will breaks down in the sun if it doesn't have a UV additive to protect it.