SolaWrap FAQ: Bursting Bubbles, Exploding Myths, and Greenhouse Fun!

🟢 What exactly is SolaWrap film? SolaWrap is not your average greenhouse covering. It's a revolutionary polyethylene bubble film designed for superior insulation, perfect for your greenhouse.

🟢 What sets SolaWrap apart from the crowd? Its unique bubble design is a game-changer, providing exceptional light diffusion and insulation. Say goodbye to average and hello to extraordinary!

🟢 Can SolaWrap handle the heat? Absolutely! SolaWrap is built tough, ready to tackle harsh weather conditions and UV exposure head-on.

🟢 But how long can it really last? SolaWrap comes with a 10-year warranty, but it often exceeds expectations with a lifespan of 15-20 years when well-maintained.

🟢 Is installation a headache? Not at all! SolaWrap is lightweight and flexible, making installation a breeze with standard tools.

🟢 What about those chilly climates? SolaWrap thrives in cold weather, offering top-notch insulation and frost resistance.

🟢 How does SolaWrap compare to traditional greenhouse coverings? Its bubble design outshines the competition, providing superior insulation, light diffusion, energy efficiency, and plant growth.

🟢 Is it as bright as glass? Brighter! SolaWrap boasts higher light transmission compared to glass, reducing the need for extra lighting and maximizing natural sunlight. Read more here

🟢 Will my plants be UV-protected? Absolutely! SolaWrap shields against harmful UV rays while still allowing beneficial UV-B rays for your plants' health.

🟢 Hail, snow, or freezing temps – is it up to the challenge? You bet! SolaWrap's tough polyethylene bubbles resist hail, insulate against freezing temps, and handle heavy snow loads.

🟢 Can it handle extreme temperatures? SolaWrap remains resilient in a wide temperature range, suited for both hot and cold climates.

🟢 What makes SolaWrap the best choice? Its advanced tech and quality materials guarantee a longer lifespan and outstanding performance – the multilayer structure is a total of 334 mil = 8.5mm = 1/3 inch

🟢 Will it save me money in the long run? Absolutely! SolaWrap's longevity and energy-saving properties make it a smart investment.

🟢 How about year-round greenhouse use? SolaWrap's stellar insulation and light diffusion create a stable environment perfect for year-round growing.

🟢 Commercial or hobbyist, does it suit both? Indeed! SolaWrap's durability and top-notch performance make it a hit for all greenhouse operations.

🟢 Going green – is SolaWrap on board? You bet! Its recyclable materials and energy efficiency support eco-friendly greenhouse practices.

🟢 Is maintenance a pain? Not at all! Occasional cleaning keeps SolaWrap in tip-top shape for years to come.

🟢 What about condensation? SolaWrap's insulation keeps condensation in check, reducing mold and disease risks.

🟢 What's the deal with hydroponics? SolaWrap's light diffusion and insulation create perfect conditions for hydroponic success and water efficiency.

🟢 Automation-friendly? You got it! SolaWrap integrates seamlessly with automated greenhouse systems.

🟢 Small-scale or home gardens – is it versatile? Absolutely! SolaWrap suits gardens of all sizes, including cozy home setups.

🟢 Frosty winters – can it keep my plants warm? SolaWrap's insulation protects your plants from frost and cold temperatures.

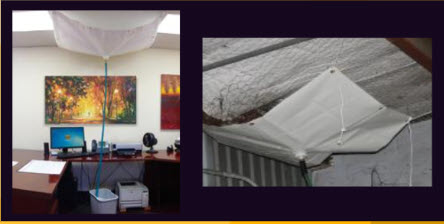

🟢 Rooftop dreams – is it a fit? SolaWrap's lightweight nature makes it perfect for rooftop greenhouse installations.

🟢 How does it help the environment? SolaWrap's energy-efficient properties reduce greenhouse gas emissions, promoting eco-friendly horticulture.

🟢 Vertical farming, anyone? SolaWrap's light diffusion and durability maximize space efficiency, ideal for vertical farming.

🟢 Bumper crops and top-notch quality – how does SolaWrap help? Superior light diffusion ensures even plant growth, leading to higher yields and better quality.

🟢 What about windy days? SolaWrap stands strong against high winds and stormy weather, offering reliable protection.

🟢 Fun fact – does it lower energy costs? SolaWrap's insulation reduces heating and cooling costs, saving you money.

🟢 UV resistant? You bet! SolaWrap can handle UV rays without yellowing or degrading.

🟢 Is it eco-conscious? Absolutely! SolaWrap is 100% recyclable, supporting environmental sustainability.

🟢 What sizes are available? SolaWrap comes in various widths, including 4', 5', and 6', with custom options for specific projects.

🟢 Curves or straight lines? SolaWrap's flexibility lets it conform to curved structures with ease.

🟢 Windy conditions – is it up for the challenge? SolaWrap's durability withstands high winds and extreme weather.

🟢 Vertical or sloped – does it work for both? SolaWrap is versatile and suits vertical and sloped walls in greenhouse construction.

🟢 Extra inflation needed for insulation? Nope! SolaWrap's bubble design provides natural insulation without additional inflation.

🟢 Perfect for hydroponics? SolaWrap's light diffusion creates ideal conditions for hydroponic growth.

🟢 Accessories-friendly? SolaWrap seamlessly works with greenhouse accessories, from fans to shade cloth.

🟢 Ideal for DIY projects? Absolutely! SolaWrap's versatility suits various DIY applications.

🟢 Mold and mildew? Not on SolaWrap's watch! Its design resists mold and mildew, ensuring a clean, healthy greenhouse.

🟢 Solar greenhouses, anyone? SolaWrap's superior light transmission maximizes sunlight for solar greenhouses.

🟢 Pest protection? SolaWrap's tight seal keeps pests out, maintaining a controlled environment.

🟢 Year-round use – is it up to the task? SolaWrap's insulation supports year-round greenhouse cultivation.

🟢 Roll-up sidewalls – does it work with them? SolaWrap pairs perfectly with roll-up sidewalls, offering easy ventilation control.

🟢 Special tools required? Nope! SolaWrap is easily installed using standard greenhouse tools.

🟢 Commercial greenhouses – is it suitable? You bet! SolaWrap caters to commercial and hobbyist greenhouses of all scales.

🟢 Chemical-resistant? SolaWrap can handle most chemicals used in greenhouse environments.

🟢 Beyond greenhouses – is it versatile? Absolutely! SolaWrap's flexibility extends to glazing various structures.

🟢 Various greenhouse designs – does it adapt? SolaWrap's flexibility allows it to conform to different designs and structures.

🟢 Frequent replacement needed? With proper care and maintenance, SolaWrap lasts over a decade without replacement.

🟢 Hot or cold, does it suit both? SolaWrap's insulation makes it ideal for both hot and cold climates in greenhouse applications.

🟢 Chemical exposure in greenhouses – is it okay? SolaWrap's materials resist common greenhouse chemicals.

🟢 Customer support available? Global Plastic Sheeting provides comprehensive support, from technical assistance to product guidance.

🟢 Ready for aquaponics? SolaWrap supports commercial aquaponic systems, enhancing plant and fish growth.

🟢 What do customers say? They rave about SolaWrap's durability, insulation, and its positive impact on plant growth and greenhouse operations.

🟢 Need a pro for installation? No need – greenhouse owners can easily install SolaWrap themselves.