Revolutionizing Industries with Engineered Plastic Sheeting Solution

Engineered flexible plastic sheeting is an innovation that has redefined durability, adaptability, and efficiency in a variety of industries. From the high demands of aerospace engineering to the resilience required in shipbuilding, its versatility has made it an indispensable material. This blog delves into its key applications in aerospace, shipbuilding, automotive, construction, and greenhouse projects, while highlighting its benefits and unique characteristics.

What is Engineered Flexible Plastic Sheeting?

Engineered flexible plastic sheeting refers to high-performance polyethylene, polyvinyl chloride (PVC), or similar materials crafted for specific industrial uses. Unlike traditional plastic films, these sheets are designed to endure extreme environments, resist wear and tear, and offer a range of technical properties like UV protection, fire retardancy, and chemical resistance.

Aerospace Applications

In aerospace, where precision and reliability are paramount, engineered flexible plastic sheeting plays a critical role.

Key Uses:

-

Protective Covering: Used to shield delicate components during manufacturing, transport, and storage.

-

Thermal Insulation: Acts as a barrier against extreme temperatures during flight.

-

Composite Materials: Integrated into carbon fiber composites to create lightweight and durable aircraft parts.

Benefits:

-

Weight Reduction: Lightweight properties contribute to fuel efficiency.

-

Durability: Resistance to UV radiation and chemicals ensures long-term performance.

Shipbuilding Applications

The shipbuilding industry demands materials that can withstand moisture, salt, and harsh marine environments. Flexible plastic sheeting is tailored to meet these challenges.

Key Uses:

-

Corrosion Prevention: Protects metal surfaces from moisture-induced rust.

-

Temporary Covers: Ensures vessels remain clean and safe during construction or repair.

-

Noise Dampening: Integrated into insulation layers to reduce onboard noise.

Benefits:

-

Enhanced Longevity: Offers superior resistance to saltwater corrosion.

-

Cost-Effective: Reduces maintenance needs through durable and reusable sheets.

Automotive Applications

In automotive manufacturing, engineered plastic sheeting has become essential for both production and end-user benefits.

Key Uses:

-

Paint Booth Liners: Prevents contamination during vehicle painting processes.

-

Interior Protection: Shields seats, dashboards, and other surfaces during assembly.

-

Soundproofing: Used in sound-dampening materials to create a quieter cabin experience.

Benefits:

-

Improved Efficiency: Streamlines production processes by minimizing contamination.

-

Noise Reduction: Enhances passenger comfort through better sound insulation.

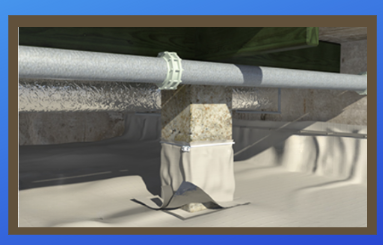

Construction Applications

Flexible plastic sheeting’s versatility makes it a staple in the construction sector.

Key Uses:

-

Vapor Barriers: Prevents moisture penetration in crawl spaces and foundations.

-

Temporary Enclosures: Protects job sites from weather conditions.

-

Reinforced Layers: Strengthens structures in roofing and concrete projects.

Benefits:

-

Weather Resistance: Withstands extreme conditions, ensuring project timelines are met.

-

Customization: Available in fire-retardant and UV-protected variants for specific needs.

Greenhouse Applications

For agricultural purposes, engineered plastic sheeting supports sustainable and efficient operations in greenhouses.

Key Uses:

-

UV Protection: Regulates sunlight exposure to optimize plant growth.

-

Temperature Control: Maintains consistent internal climates.

-

Durability: Resists wear from external environmental factors like wind and rain.

Benefits:

-

Cost Savings: Reduces the need for frequent replacements.

-

Enhanced Yield: Supports healthier and more consistent crop production.

Why Choose Engineered Flexible Plastic Sheeting?

-

Adaptability: Tailored for diverse environments and applications.

-

Durability: Offers high resistance to physical, chemical, and environmental stresses.

-

Sustainability: Many options are recyclable, reducing environmental impact.

-

Efficiency: Improves operational workflows across industries.

Conclusion

Engineered flexible plastic sheeting continues to evolve as an indispensable material across aerospace, shipbuilding, automotive, construction, and greenhouse sectors. Its unmatched durability, adaptability, and efficiency ensure that it meets the unique demands of each industry. By investing in high-quality plastic sheeting, businesses can optimize their operations and deliver better results.

Whether you’re shielding sensitive equipment or creating robust structures, engineered flexible plastic sheeting provides innovative solutions tailored to today’s industrial challenges.