On March 27, 1933, two organic chemists working for the Imperial Chemical Industries Research Laboratory were testing various chemicals. To R.O Gibson and E.W. Fawcett's surprise the white, waxy substance they were testing would become a revolutionary substance that would change the world. Polyethylene was born!

The researchers set off a reaction between ethylene and benzaldehyde, in an autoclave. It seems their testing container sprang a leak and all of the pressure escaped. There was the white, waxy substance that greatly resembled plastic. Upon carefully repeating and analyzing the experiment, the scientists discovered that the loss of pressure was only partly due to a leak; the major reason was the polymerization process that had occurred leaving behind polyethylene. The first patents for polythene were registered in 1936 by Imperial Chemical Industries. A year later the first practical use for the material, as a film, was discovered. In 1953 Karl Ziegler of the Kaiser Wilhelm Institute and Erhard Holzkamp invented HDPE (High Density Polyethylene). From there, two years later, in 1955, HDPE was produced as pipe. Ziegler was awarded the 1963 Nobel Prize for Chemistry.

Did you know that polyethylene played a key supporting role during World War II? It was first used as an underwater cable coating and then as a critical insulating material for vital military applications as radar insulation. This is because it was so light and thin that it made placing radar onto airplanes possible thus vastly reducing the weigh. The substance was a highly guarded secret.

After the war, polyethylene became a tremendous hit with consumers It became the first plastic in the United States to sell more than a billion pounds a year. It is currently the largest volume plastic in the world.

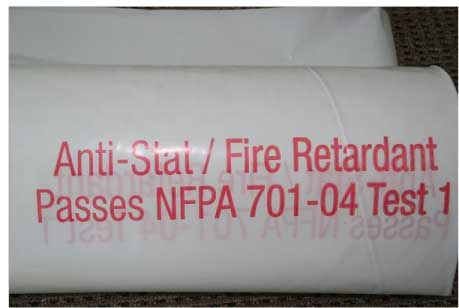

Today, Polyethylene has the advantages of excellent moisture-vapor, chemical, and electrical resistance. It is widely used for making containers, wire cable insulation, pipe, linings, coatings, and engineered films. It is used to power transmission, consumer goods, packaging, electronics household good and more. Its principal disadvantage is poor mechanical strength, unless it has a little help from scrim reinforcement! Developments in technology continues to improve its functionality making it the most efficient use of natural resources petroleum and natural gas. We applaud these scientists for creating polyethylene that is used in a variety of plastic sheeting products today.

Polyethylene is the largest volume polymer produced globally, with over 90 million metric tons per year!

Click HERE to visit the resource page to visit the applications pages for

Click HERE to visit the resource page to visit the applications pages for

*Plastic Sheeting - thickness for what application

* Tapes- thicknesses and applications

* Enka Products applications and options

and many more products.

One thing to be aware of is the plastic ripping where the plastic touches the PVC. This seems to be reported from growers who don't use a film that offers UV protection The PVC may absorb the heat and speed up the breakdown of the plastic. As we all know, sun is an enemy to all sorts of plastic sheeting. Another reason for the breakdown and tearing of the plastic could be the chlorine that is in PVC. This too is a problem for greenhouse plastic. There is a polyethylene greenhouse film that won't give you these problems called SolaWrap! Read on to learn more.

One thing to be aware of is the plastic ripping where the plastic touches the PVC. This seems to be reported from growers who don't use a film that offers UV protection The PVC may absorb the heat and speed up the breakdown of the plastic. As we all know, sun is an enemy to all sorts of plastic sheeting. Another reason for the breakdown and tearing of the plastic could be the chlorine that is in PVC. This too is a problem for greenhouse plastic. There is a polyethylene greenhouse film that won't give you these problems called SolaWrap! Read on to learn more.