Vapor Barrier vs Vapor Retarder....What's the difference?

People often use these two terms vapor barrier and vapor retarder interchangeably but....there is a difference.

Vapor barrier:

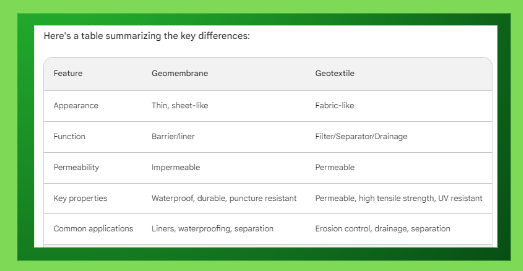

- Nearly impermeable: A vapor barrier aims to completely block the movement of water vapor through it. This is typically achieved with materials like aluminum foil or high-density polyethylene sheeting.

- Stricter definition: The International Residential Code (IRC) doesn't define "vapor barrier," but some manufacturers and professionals use it to signify a Class I vapor retarder with a perm rating of 0.1 or less.

- Less forgiving: Due to its near-impermeability, a vapor barrier can trap moisture if installed incorrectly or in the wrong conditions. This can lead to problems like condensation and mold growth in certain situations.

Vapor retarder:

- Partially restricts: A vapor retarder slows down the movement of water vapor but doesn't completely block it. This allows some moisture to pass through under controlled conditions.

- Broader category: The IRC recognizes different classes of vapor retarders (I, II, and III) with varying perm ratings (0.1 to 1.0). Different materials like specific plastic sheeting and tarps can fall under this umbrella.

- More adaptable: Due to its ability to allow some moisture movement, a vapor retarder can be more forgiving in certain applications where perfect sealing isn't crucial.

In summary:

- Think of a vapor barrier as a strict "stop sign" for water vapor.

- Think of a vapor retarder as a "slow down" sign, allowing some controlled movement.

Vapor barriers/ vapor retarders play a crucial role in keeping your home comfy, healthy, and energy-efficient. But what exactly do they do, and why might you need one? Buckle up, friends, because we're about to peel back the layers on this essential building material!

Imagine your home as a superhero cape, protecting you from the elements. Moisture from the ground is like a sneaky villain, trying to seep in and wreak havoc. That's where the vapor retarder steps in – it's your moisture-fighting sidekick, forming a barrier to keep that villain at bay.

Here's why having a trusty vapor retarder is just like having a loyal sidekick:

1. Shields against moisture damage: Moisture buildup can lead to a host of problems, from mold and mildew (ew!) to warped floors and rotting wood. A vapor retarder says "not today, moisture!" keeping your home dry and healthy.

2. Boosts energy efficiency: When your home is constantly battling moisture, it has to work overtime to stay comfortable. A vapor retarder reduces that struggle, meaning lower energy bills and a happier planet.

3. Protects sensitive areas: Some places, like cold storage and museums, demand extra moisture control. A vapor retarder like Griffolyn® VaporGuard® comes to the rescue with its superhero strength:

- Triple-layer armor: Multiple polyethylene layers and an aluminum core create an impenetrable fortress against moisture. Say goodbye to punctures and tears!

- Sun-resistant shield: No need to worry about this hero fading in the sun. VaporGuard's UV protection keeps it strong and ready for action.

- Cold-weather warrior: Even the chilliest winters can't crack this cold-resistant champion. VaporGuard stays flexible and effective no matter the temperature.

- Chemical-proof defense: No nasty chemicals can harm this hero. VaporGuard stands strong against whatever gets thrown its way.

- Lightweight agility: Installing VaporGuard is a breeze thanks to its flexible and lightweight design. Quick and easy protection? Sign us up!

But where can this mighty hero be deployed? VaporGuard has your back in many situations:

- Underneath your concrete slab: Keeping moisture from rising up into your living space.

- On walls and ceilings: Protecting against condensation and leaks.

- In roofing systems: Ensuring your attic stays dry and comfortable.

- And beyond!: From dust partitions to landfill covers, VaporGuard's versatility knows no bounds.

So, is a vapor retarder right for you? If you live in a humid area, have a crawl space, or simply want to ensure your home's long-term well-being, the answer is a resounding yes! Griffolyn® VaporGuard® is your ultimate sidekick in the fight against moisture. With its superior strength, flexibility, and adaptability, it's the hero your home needs.

Remember, a healthy home starts with a happy vapor retarder. So, let VaporGuard® join your team and watch your home thrive!

Disclaimer: Please consult with a building professional to determine the specific needs of your project and ensure proper installation of any vapor retarder.