How is Polypropylene different from Polyethylene? Well.....

Polypropylene, also know as polypropene is a form of plastic just as polyethylene is. What separates polypropylene from polyethylene for starters is the fact that polypropylene can be molded in essence becoming pliable above a certain temperature. When it cools it will return to its solid state. Polypropylene can be used not only as a structural plastic, but it can be used as a fiber. It also has a high melting point, which differentiates it from polyethylene. One area where polyethylene has over polypropylene is that polyethylene is more stable. Polypropylene has the advantage that it can take repeated motions such as being a hinge. A hinge made out of polypropylene can be opened and closed many many times, and hold up just fine. This is known as having "good resistance to fatigue". MORE

Polypropylene can be combined with other materials, as can polyethylene. Rubber for example can be added, to make it more pliable. One of the exciting additives that is added to polypropylene are minerals. These minerals allow a polypropylene sheet to become a synthetic paper. synthetic paper is essentially plastic paper. It can be easily printed on. It can be folded, hot stamped, die cut, sewn and more. Best of all it is environmentally friendly! All of a sudden polypropylene is transformed into a slew of products. Synthetic paper made from polypropylene is used to make banners, membership cards, maps, menus, phone cards, signs, tags, floor graphics, counter mats, and booklets. The list goes on from here! What is outstanding about synthetic paper is that is is durable, tear and water resistant!(Products made from polypropylene)

Polyethylene has more demand however than polypropylene. Polypropylene is used extensively in the automotive industry as well as the packaging industry. 70% of the polypropylene uses is for packaging needs for the food industry. It can be made into bottles, food containers, food crates and pallets.

Polypropylene is used to make house wears, appliances and toys. It is also used to make make carpeting and upholstery. The polypropylene is heated and made into fibers. There are so many uses for both polypropylene and polyethylene.

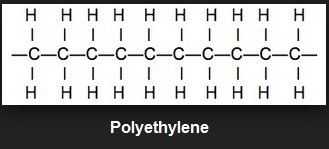

Polyethylene is inert, translucent and creates a lower static charge than polypropylene. That makes polyethylene a candidate to be a sleeve to house collectible documents. It is "inert" and cannot product mold or mildew. It is also translucent in nature so it allows less light through it than polypropylene. It has a lower static charge than polypropylene so it attracts less dust and dirt. Polyethylene costs more than polpropylene because it has a higher purity (100% virgin).

Here is a list of some of the differences between polyethylene and polypropylene:

- Polyethylene and Polypropylene are very similar as far as physical properties.

- However, Polyethylene can be produced optically clear where polypropylene can only be made translucent like a milk jug.

- Polyethylene does have physical properties that allow it to stand up better in cold temperatures, particularly when using it as signs.

- Polyethylene is a good electrical insulator. It offers good tracking resistance, however, it becomes easily electrostatically charged (which can be reduced by additions of graphite, carbon black or antistatic agents).

- Polypropylenes are light in weight. They have a high resistance to cracking, acids, organic solvents and electrolytes. They also have high melting point and good dielectric properties and are non-toxic.

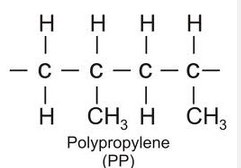

- Monomer of polyethylene is ethylene and monomer of polypropylene is propylene.

- Polyethylene has a lower melting point compared to the higher melting point of polypropylene. (this may be a good test for you)

- Polypropylene is not as sturdy as polyethylene.

- Polypropylene is stiffer and resistant to chemicals and organic solvents compared to polyethylene.

- Polypropylene is pure, non-stretching and generally more rigid than polyethylene.