Construction Grade Plastic Sheeting

Construction grade polyethylene sheeting serves may purposes for construction jobs and homeowners alike.

This durable sheeting provides protection against water vapor and foreign matter. Great for use in concrete curing, construction, and remodeling.

Rolls come in a variety of lengths and widths for small and large-scale projects.

Please note: Construction grade plastic is not the same thing as "Constuction Plastic". Construction grade plastic contains recycled materials, causing the clear film to be opaque. It does not contain a UV inhibitor, and is not intended for outdoor projects where it will be exposed to direct sunlight for an extended period of time.

Product Information:

Thickness: .7 - 10 mil

Color: Clear, Black

Material: LDPE, PELD

Tensile Strength: Varies by mil - see spec sheet

Manufacturing Technology: Extrusion Moulding, Extrusion Blow Moulding

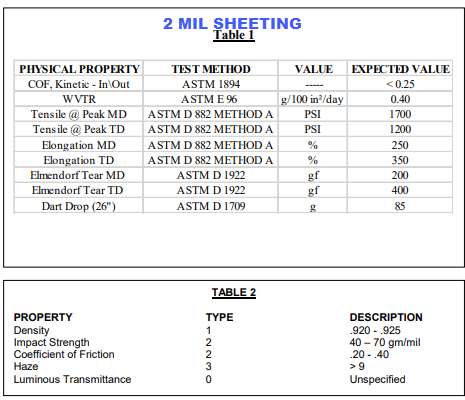

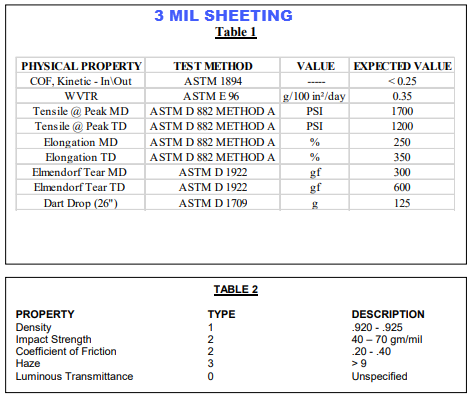

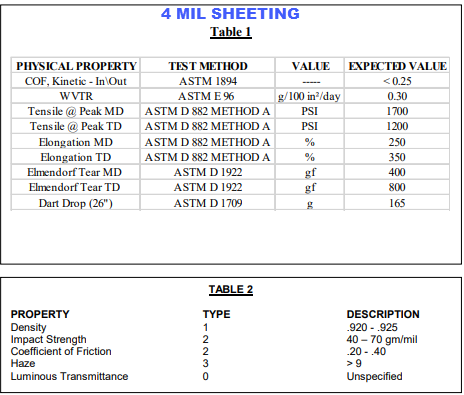

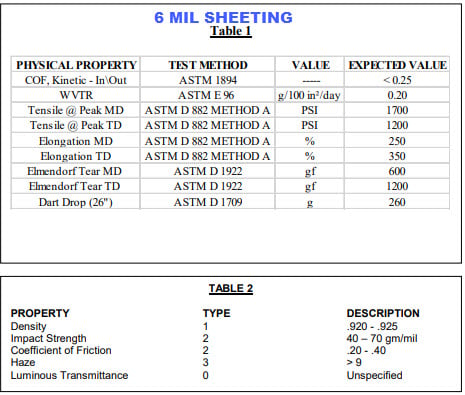

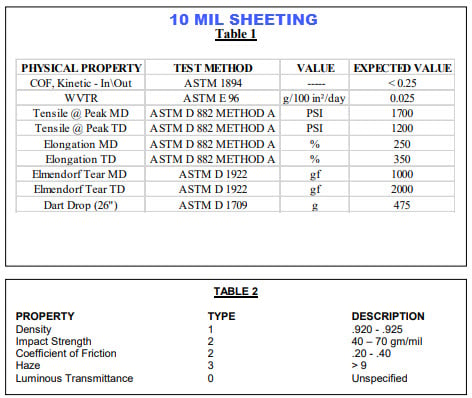

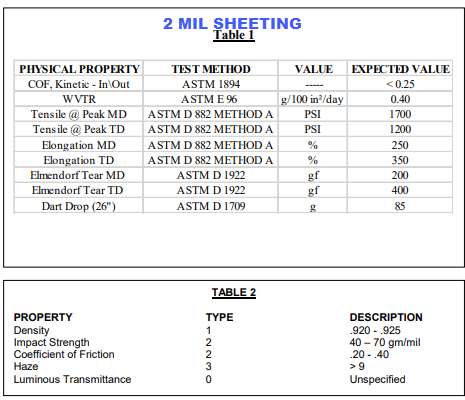

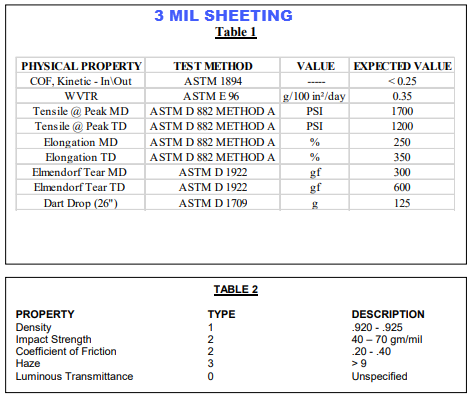

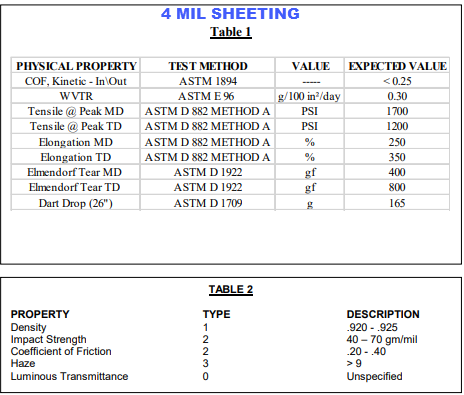

Construction-Grade Polyethylene Data Information for Films 2 mil, 3 mil, 4 mil, 6 mil, 8 mil and 10 mil

1. PRODUCT NAME

Construction-Grade Polyethylene Sheeting designed for general purpose construction, agricultural, and industrial usage.

2. DISTRIBUTOR:

Global Plastic Sheeting, Inc

Chula Vista, CA 91911

3. Scope

Specification covers both black and clear 2, 3, 4, 5, 6, 8, and 10 mil sizes.

4. General Information

A. Basic Uses

Global Plastic Sheeting’ polyethylene sheeting is used in a wide variety of applications. Polyethylene provides an excellent vapor barrier for the protection of concrete slabs and foundations. Proper placement of polyethylene sheeting in walls during construction can almost completely prevent ambient air and moisture

infiltration into homes and buildings, thus increasing their energy efficiency.

Agricultural applications (black sheeting only) include retention of soil moisture, inhibition of weed growth, and coverage of pit and trench silos

for inexpensive storage.

B. Life Expectancy

Product does not include UV inhibitor. Clear polyethylene sheeting is not recommended for greenhouse use or any other application involving long term exposure to sunlight. Black sheeting is recommended for applications not exceeding 90 days of sunlight exposure. Special additives are available at request

for extended outdoor applications up to 2 years.

C. Shelf Life

Polyethylene sheeting has a shelf life of approximately 2 years if not exposed to sunlight or extreme heat.

D. Other Limitations

Request information on these and other limitations that may or may not apply depending on the specific application and product.

E. Adhesion

Due to the variety of resins and additives available, it is often difficult to bond two pieces of film together. Two adhesives that have proven to be successful in the past are Universal Adhesives’ Spray Adhesive and DURO All Purpose Spray Adhesive distributed by Loctite Corporation.

F. Temperature Range

Usable range for LDPE has been defined as -60F to 150 F

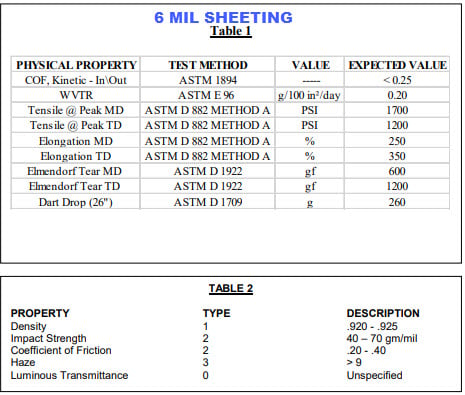

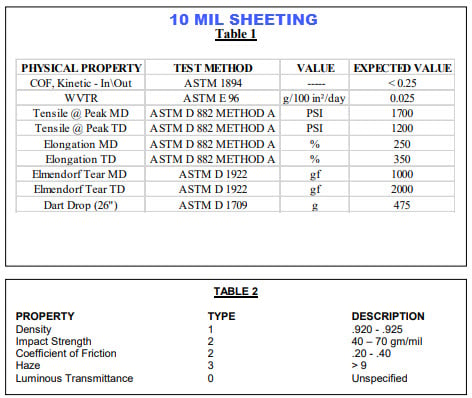

ASTM D4397 Meets specs as outlined in table 1 below.

NIST 133 Film weight is calculated as required by the National Institute Standards Technology.

ASTM E154-99 Water vapor retarders used in contact with earth under concrete slabs, on walls or as ground cover.

PS 17-69 Public Standards 17.

ASTM C171 Standard Specification for Sheet Materials Used for Curing Concrete

5. Technical Data

Global Plastic Sheeting’s polyethylene sheeting complies with most national, state and local specifications for concrete curing, vapor barrier applications, and

other uses involving polyethylene sheeting. LP378 Type 1, Class 1, Grade B, and Finish 1.

6. Recyclability

This sheeting is rated as a CLASS 4 – LDPE for recycling purposes. The information presented on this data sheet/ web page has been established by company based laboratory testing. This information does not imply warranty by the company of product specifications, tolerances, or function in the end use.