Floating Baffles- What do They Do?

A floating baffle is a device used in various water treatment applications to control and direct the flow of water. It is typically made of durable materials and designed to float on the surface of a water body, such as a pond, lake, or wastewater treatment tank. The primary purpose of a floating baffle is to improve the efficiency of water treatment processes by separating different zones or compartments within the water body. Floating baffles work by creating a series of small channels through which water flows. This helps to distribute the water evenly throughout the treatment system, and it also helps to prevent short-circuiting, which is a problem that can occur when water flows too quickly through a treatment system.

Where are Floating Baffles Used?

Floating baffles are commonly used in wastewater treatment plants to enhance the performance of settling tanks and clarify the water. They create distinct sections within the tank, allowing for the separation of solids from liquid and promoting the settling of suspended particles. This helps to improve the overall treatment efficiency and ensures cleaner water is discharged.

These baffles are also utilized in stormwater ponds and retention basins to manage the flow of water and promote sedimentation. By strategically placing floating baffles, the water can be directed in a controlled manner, reducing the velocity and allowing sediment to settle out before the water is discharged.

How are Floating Baffles Created?

Floating baffles can be created using various materials, depending on the specific application and requirements. Common materials used for their construction include high-density polyethylene (HDPE), reinforced geomembranes, such as XR-5, and other durable plastics. These materials are chosen for their resistance to chemicals, UV degradation, and ability to withstand the environmental conditions present in water treatment settings.

What Thickness of HDPE is used for Floating Baffles? Click here

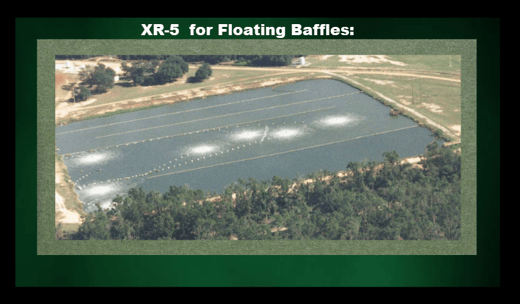

XR-5 For Floating Baffles- Click here

XR-5 Geomembranes are used for the principal construction material in floating diversion baffles.

The design and configuration of floating baffles may vary depending on the desired outcomes and specific site conditions. They can be customized to fit the dimensions and layout of the water body, ensuring optimal performance and effectiveness in directing water flow and facilitating the treatment process.

In summary, floating baffles are essential tools in water treatment systems, providing separation, control, and improved efficiency. They play a crucial role in managing the flow of water, promoting sedimentation, and enhancing the overall performance of settling tanks and treatment processes.