Unveiling the Secrets of Crawlspace Liners: Why All Plastic Liners Won't Cut It for Your Home

Introduction: For many homeowners, the crawl space beneath their home might seem like an afterthought, out of sight and out of mind. However, understanding the importance of proper insulation and moisture control in this space can have a significant impact on the overall health and longevity of your home. In this article, we're delving into the world of crawlspace liners, specifically exploring the differences between Class A, B, and C liners of ASTM E-1745 standards. We'll also uncover why using visqueen, a common plastic sheeting, falls short in this critical role.

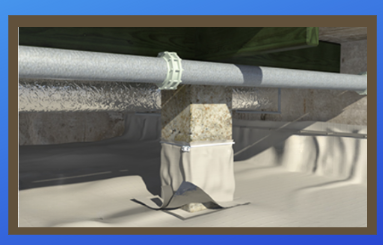

The Role of Crawlspace Liners: Crawlspace liners are essential barriers designed to control moisture and protect the structural integrity of your home. They create a shield between the ground and the lower levels of your home, helping to prevent excess moisture, mold growth, and structural damage.

Class A, B, and C Liners: Understanding the Standards: ASTM E-1745 sets the standards for crawlspace liners, categorizing them into three classes based on their performance and effectiveness:

-

Class A Liners: These liners are highly effective in preventing moisture penetration. They are designed to withstand high levels of water exposure, making them suitable for areas with significant groundwater issues or high humidity levels.

-

Class B Liners: These liners provide a balanced level of moisture protection. They are ideal for areas with moderate moisture levels and are effective in guarding against common moisture sources.

-

Class C Liners: These liners offer basic moisture protection. They are suited for areas with minimal moisture concerns and provide a basic level of defense against minor moisture intrusion.

Behind ASTM-E 1745: Ensuring Quality Standards

ASTM E 1745, the standard governing crawlspace liners, is developed and maintained by the American Society for Testing and Materials (ASTM International). This organization is a globally recognized leader in establishing technical standards across various industries, including construction and materials testing. The ASTM-E 1745 standard has been meticulously crafted by a committee of experts, including engineers, scientists, and industry professionals. Their collective expertise ensures that the standard reflects the most advanced knowledge and best practices in moisture control and material performance.

Understanding Permeability/ Permeance and ASTM E 1745 Specifications

Permeability is a crucial concept when it comes to moisture control. It refers to the rate at which moisture vapor passes through a material. Permeability is measured in perms – a unit indicating the amount of moisture that can permeate a material within a specified time and area.

The specifications for ASTM E 1745 Class A, Class B, and Class C liners are as follows:

- Class A Liner: Maximum permeability of 0.1 perms, minimum tensile strength of 45 lb/in, and a minimum puncture resistance of 2200 grams.

- Class B Liner: Maximum permeability of 0.1 perms, minimum tensile strength of 30 lb/in, and a minimum puncture resistance of 1700 grams.

- Class C Liner: Maximum permeability of 0.1 perms, minimum tensile strength of 13.6 lb/in, and a minimum puncture resistance of 475 grams.

Distinguishing Class 1 and Class 2 Vapor Retarders

The classification of vapor retarders refers to their effectiveness in slowing down the movement of moisture vapor. Class 1 vapor retarders have a lower permeance, indicating greater resistance to moisture movement. On the other hand, Class 2 vapor retarders allow slightly more moisture to pass through. The choice between Class 1 and Class 2 depends on factors such as climate, building design, and intended use.

Choosing the Right Vapor Barrier Class

When selecting a vapor barrier class, several factors come into play.

- Class A vapor barriers are ideal for areas with high moisture levels, such as regions with significant groundwater concerns or heavy humidity.

- Class B vapor barriers offer a balanced level of protection and are suitable for regions with moderate moisture challenges.

- Class C vapor barriers are effective in areas with minimal moisture concerns. Your choice depends on the specific moisture conditions in your crawl space and the level of protection required to maintain a dry and healthy environment.

How is it that All Plastic Sheeting isn't The Same?

Moisture can penetrate plastic liners due to a property called PERMEANCE which refers to the ability of a material to allow water vapor to pass through it. Some plastic liners have higher permeance values, which means they are more permeable to moisture, while others have lower permeance values, making them less permeable. The goal of creating liners with low permeance is to effectively block moisture from infiltrating the material and entering the protected space, such as a crawl space.

Manufacturers achieve low permeance in plastic liners by carefully selecting materials and employing spec ific manufacturing techniques. Here's how they do it:

-

Material Selection: Manufacturers choose materials with inherently low permeance properties. High-quality plastic resins with tight molecular structures and minimal gaps or pores are preferred. These materials naturally offer greater resistance to moisture vapor transmission.

-

Barrier Coatings: Some plastic liners receive special coatings or treatments that further enhance their impermeability. These coatings can create a barrier that reduces the ability of moisture molecules to pass through the material.

-

Lamination: Some liners are created by laminating multiple layers of plastic with different properties. By combining layers with varying permeance levels, manufacturers can create a liner that effectively resists moisture intrusion.

-

Polymer Blends: Manufacturers may blend different types of polymers to create a liner with optimal impermeability characteristics. This process allows them to harness the strengths of different materials to achieve the desired moisture resistance.

-

Advanced Manufacturing Techniques: Special manufacturing processes, such as extrusion or calendering, can create liners with consistent thickness and uniform permeance levels. This ensures that the liner's impermeability is maintained throughout its structure.

A Chain Link Fence Versus a Solid Cement Wall- An Analogy for a Crawl Space Liner

Imagine your crawl space liner as a protective barrier, much like comparing a chain-link fence to a solid cement wall. Both serve the purpose of separating spaces and keeping certain things out. However, they differ in their effectiveness against specific elements, such as sand.

A chain-link fence, while effective in keeping out larger objects and providing a visible boundary, allows smaller particles like sand to easily pass through its gaps. Similarly, certain plastic liners with higher permeance values can block larger water molecules but might allow moisture vapor, like sand particles, to infiltrate.

On the other hand, a solid cement wall provides a more impenetrable barrier. It prevents the passage of both large and small particles, effectively stopping sand from passing through. In the same way, plastic liners with lower permeance values act as a more robust barrier against moisture, blocking not only larger water droplets but also the vapor that could seep through gaps in less effective liners.

Just as a cement wall is a more reliable barrier against sand than a chain-link fence, a crawl space liner with lower permeance is a more reliable defense against moisture intrusion than one with higher permeance. By choosing a liner with low permeance and adhering to industry standards, homeowners can ensure that their crawl space remains effectively protected from moisture-related issues.

Why Visqueen Falls Short: Visqueen, a type of plastic sheeting often found in hardware stores, is not a suitable substitute for ASTM E-1745 liners. While it might appear to offer a barrier against moisture, it lacks the specialized features necessary to combat moisture effectively in a crawlspace environment. Visqueen is not designed to withstand the moisture levels, ground gases, and potential abrasions that can occur in a crawlspace.

The Permeability of Concrete and the Importance of Liner Selection: Concrete, though solid, is not impermeable to moisture. Water can seep through concrete, leading to dampness and the potential for mold growth. Selecting the right crawlspace liner is crucial because it acts as a reliable shield against this moisture infiltration.

Do All Buildings Require a Crawl Space Liner?

While crawl space liners are beneficial for many buildings, whether a building needs one depends on various factors, including climate, geographical location, building design, and moisture levels. Crawl space liners are especially important in regions with high humidity, heavy rainfall, or significant groundwater concerns. These liners help prevent moisture intrusion, mold growth, and structural damage.

However, in arid regions or areas with low moisture levels, the need for a crawl space liner might be less critical. In such cases, the moisture-related risks are lower, and the building's design and construction methods might already account for these conditions.

States with predominantly dry climates, such as those in the southwestern United States, might have fewer instances where crawl space liners are considered essential. Conversely, states with higher humidity and more frequent rain, such as those along the Gulf Coast or in the Northeast, often see a greater need for crawl space moisture control solutions.

Conclusion: Your home's crawlspace deserves attention and thoughtful consideration when it comes to moisture control. Properly selected and installed crawlspace liners, in accordance with ASTM E-1745 standards, can make a significant difference in protecting your home's foundation, structural integrity, and overall air quality. While visqueen might suffice for temporary applications, it falls short in the long-term moisture control required in a crawlspace environment. By understanding the differences between Class A, B, and C liners, homeowners can make an informed choice to ensure their home remains a safe and sound haven for years to come.