Let's start at the beginning so we are on the same page.

What is the difference between a geomembrane and a geotextile?

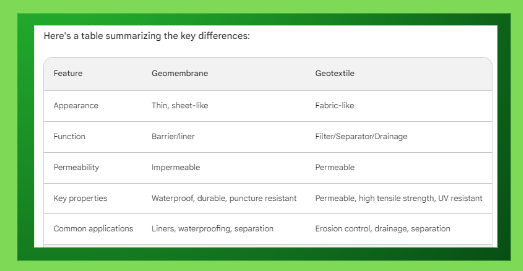

While both geomembranes and geotextiles are geosynthetics used in construction and civil engineering, they have distinct differences in function and appearance:

Geomembrane:

- Appearance: Thin, sheet-like material, often plastic or rubber-based. It can be smooth or textured.

- Function: Primarily acts as a barrier or liner to prevent fluids (water, gases, chemicals) from passing through.

- Key properties: Waterproof, impermeable, durable, puncture resistant, chemical resistant.

- Common applications: Landfill liners, pond liners, canal liners, foundation and roof waterproofing, drainage applications (pond liners), separation layers, vapor barriers.

Geotextile:

- Appearance: Fabric-like material, woven or non-woven, made from synthetic or natural fibers.

- Function: Primarily acts as a filter, separator, or drainage layer.

- Key properties: Permeable, allows water to pass through while filtering out soil particles, high tensile strength, resistant to UV degradation.

- Common applications: Erosion control, soil stabilization, drainage systems, road and railway construction, landscaping, filtration layers, separation layers between soil and aggregate.

1. What is non-woven geotextile fabric?

- Answer: Non-woven geotextile fabric is a synthetic material made by mechanically binding or chemically bonding fibers. It is widely used in civil engineering and construction for various applications such as drainage, filtration, separation, and erosion control.

2. What is the difference between woven and non-woven geotextile membranes?

- Answer: Woven geotextiles are made by weaving fibers together, providing strength and stability. Non-woven geotextiles, on the other hand, are made by bonding fibers, offering filtration and drainage properties. Non-woven fabrics are more versatile in drainage applications.

3. What is the difference between geogrid and non-woven geotextile?

- Answer: Geogrid is a mesh-like material used for soil reinforcement, offering tensile strength. Non-woven geotextile primarily serves for filtration and drainage purposes. Geogrid is ideal for stabilizing soils, while non-woven geotextile manages water flow.

4. Can water pass through geotextile fabric?

- Answer: Yes, water can pass through geotextile fabric. Non-woven geotextiles are designed to allow water to permeate while providing filtration, preventing soil erosion and ensuring effective drainage.

5. How long does non-woven geotextile last?

- Answer: The lifespan of non-woven geotextile depends on factors like material quality, exposure to environmental conditions, and the specific application. Generally, high-quality non-woven geotextiles can last anywhere from 20 to 50 years.

6. Why use non-woven geotextile?

- Answer: Non-woven geotextiles offer versatile solutions for various applications such as drainage, filtration, and separation in construction and civil engineering projects. They are cost-effective, lightweight, and provide reliable performance in preventing soil erosion and managing water flow.

Understanding the Power of Ounces: A Guide to Geotextile Thickness

The humble ounce plays a surprisingly influential role in the world of geotextiles. These seemingly insignificant weight variations translate into distinct performance differences, tailoring each fabric to specific applications. Fpr example:

The flow rate of 4 oz geotextiles can vary depending on factors such as the specific manufacturing process, material composition, and design considerations of each product. Different manufacturers may employ variations in technology and materials, leading to variations in the performance characteristics, including flow rates, of their 4 oz geotextiles.

It's essential to refer to the product specifications provided by the manufacturer for accurate and detailed information about the flow rate of a particular 4 oz geotextile. Additionally, consulting with the manufacturer or supplier directly can offer insights into the specific performance attributes and capabilities of their geotextile products.

Let's delve into the world of ounce power by exploring the characteristics of various geotextile weights:

Understanding the Flow Rate:

Flow rate (gpm/ft²) indicates the volume of water a geotextile can pass through per minute per square foot. Higher ounces generally handle greater water flow due to their thicker and more open-weave structure. Consider your drainage needs when choosing the right weight.

Beyond Ounces:

Remember, ounce is just one factor to consider. Material type (woven vs. non-woven), fiber composition, and UV resistance also play crucial roles. Consult with a professional for specific recommendations based on your project requirements.

Bonus Tip: Overlaying lighter weight geotextiles can create the desired strength and filtration properties for unique situations.

So, the next time you encounter a geotextile, remember the hidden power within its ounces. Choose wisely, and your projects will be rewarded with lasting success!

Visit the Non-woven geotextile product page here.