Growing The Beloved Cucumber!

Introduction:

Cucumbers are crisp, refreshing, and a staple ingredient in salads, sandwiches, and pickles. Growing cucumbers in greenhouses offers numerous advantages, allowing gardeners to enjoy a bountiful harvest and extend the growing season. In this comprehensive guide, we will explore the pros and cons of greenhouse cucumber cultivation, delve into the speed of growth, and uncover some fascinating fun facts about these versatile vegetables.

Pros of Growing Cucumbers in Greenhouses:

-

Extended Growing Season: Greenhouses provide a controlled environment that allows cucumbers to be grown beyond their normal outdoor growing season. With the ability to manipulate temperature, humidity, and light, greenhouse growers can enjoy a longer cucumber harvest and meet market demands year-round.

-

Higher Yields: The controlled conditions in a greenhouse optimize cucumber growth, resulting in higher yields compared to outdoor cultivation. Cucumbers grown in greenhouses receive consistent care and protection against adverse weather conditions, pests, and diseases, leading to healthier plants and increased production.

-

Protection from External Factors: Greenhouses shield cucumbers from external factors that can hinder their growth, such as extreme temperatures, heavy rain, or strong winds. This protection creates a more stable environment, reducing stress on the plants and ensuring optimal growth.

-

Better Quality and Appearance: Greenhouse-grown cucumbers often exhibit superior quality and appearance. The controlled environment allows for consistent watering, nutrient supply, and lighting conditions, resulting in uniform fruit size, shape, and color. They are less likely to be blemished or scarred, making them more visually appealing to consumers.

Cons of Growing Cucumbers in Greenhouses:

-

Higher Initial Investment: Setting up a greenhouse for cucumber cultivation requires an initial investment in infrastructure, including the greenhouse structure, ventilation systems, heating, and lighting. These costs should be considered when evaluating the feasibility of greenhouse cucumber production.

-

Energy Consumption: Greenhouses require energy for heating, cooling, and maintaining optimal growing conditions. This energy consumption adds to the overall cost of greenhouse cucumber cultivation and contributes to environmental impact.

Speed of Growth and Percentages:

Cucumbers are known for their rapid growth rate, especially in the controlled environment of a greenhouse. On average, greenhouse cucumbers take approximately 50 to 70 days from planting to harvest, depending on the variety and growing conditions. This accelerated growth allows for multiple harvests within a single growing season.

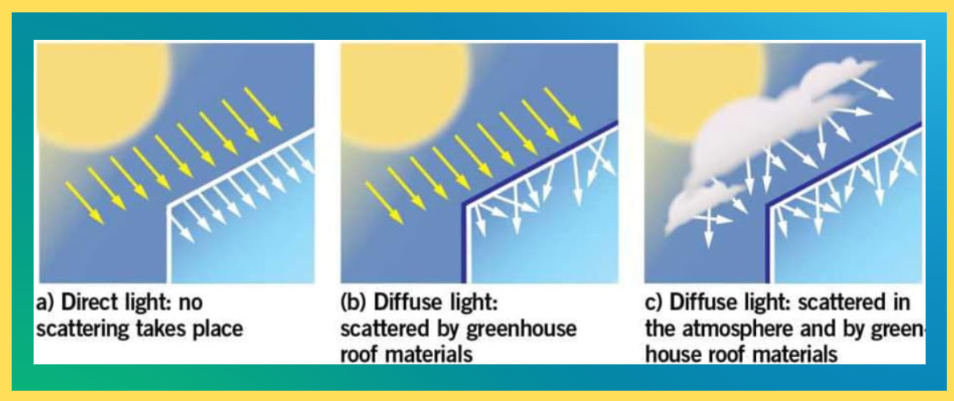

Please visit our Greenhouse Films Page.

Fun Facts about Cucumbers:

-

Cucumbers are 95% water, making them an excellent hydrating snack.

-

They belong to the same plant family as melons and pumpkins, known as the Cucurbitaceae family.

-

The world's longest cucumber measured over 47 inches (120 cm)!

-

Cucumbers contain antioxidants and vitamins that can promote skin health and hydration.

-

"Burpless" cucumber varieties have lower levels of cucurbitacin, a compound that can cause bitterness and indigestion.

Conclusion:

Growing cucumbers in greenhouses offers numerous advantages, including extended growing seasons, higher yields, and protection against external factors. While there are initial investment costs and energy consumption to consider, the benefits of greenhouse cucumber cultivation outweigh the drawbacks for many gardeners. With their rapid growth and interesting fun facts, cucumbers are a versatile and rewarding crop to cultivate in a greenhouse. So, get ready to enjoy the crispness and flavor of homegrown cucumbers all year round with the help of a greenhouse!

Asian Cucumber Salad:

Ingredients:

- 2 cucumbers, thinly sliced

- 2 tablespoons rice vinegar

- 1 tablespoon soy sauce

- 1 teaspoon sesame oil

- 1 teaspoon honey or sugar

- 1 clove garlic, minced

- 1/2 teaspoon grated ginger

- 1/2 teaspoon red pepper flakes (optional)

- 1 green onion, thinly sliced

- Toasted sesame seeds for garnish

Instructions:

- Place the thinly sliced cucumbers in a bowl.

- In a separate small bowl, whisk together the rice vinegar, soy sauce, sesame oil, honey or sugar, minced garlic, grated ginger, and red pepper flakes (if using).

- Pour the dressing over the cucumbers and toss well to ensure they are evenly coated.

- Let the salad marinate in the refrigerator for at least 30 minutes to allow the flavors to meld together.

- Before serving, garnish with thinly sliced green onions and toasted sesame seeds.

- Serve chilled as a refreshing side dish or accompaniment to Asian-inspired meals.

Note: You can customize this recipe by adding other ingredients like sliced red bell peppers, shredded carrots, or chopped cilantro for additional flavors and textures. Adjust the amount of red pepper flakes based on your spice preference. Enjoy the crisp and tangy flavors of this Asian-inspired cucumber salad!