Hydraulic fracturing, also known as fracking, is a technique used in the extraction of natural gas and oil from underground reservoirs.

It involves injecting a mixture of water, sand, and chemicals at high pressure into rock formations deep below the Earth's surface. The purpose of this process is to create fractures or fissures in the rock, allowing the trapped gas or oil to flow more freely and be extracted.

The Process of Hydraulic Fracturing:

-

Hydraulic fracturing, also known as fracking, is a technique used in the extraction of natural gas and oil from underground reservoirs. It involves injecting a mixture of water, sand, and chemicals at high pressure into rock formations deep below the Earth's surface. The purpose of this process is to create fractures or fissures in the rock, allowing the trapped gas or oil to flow more freely and be extracted.

The Process of Hydraulic Fracturing:

-

Well Drilling: A well is drilled vertically into the ground, typically reaching thousands of feet below the surface. Once the desired depth is reached, the drill bit is redirected horizontally to access a larger area of the underground reservoir.

-

Well Casing and Cementing: Steel casing is inserted into the well, and cement is then pumped into the space between the casing and the surrounding rock formations. This helps to secure the well and prevent any potential contamination of groundwater.

-

Fracturing Fluid Injection: A mixture of water, sand (proppant), and chemicals is pumped into the well at high pressure. The water acts as the main carrier, while the sand props open the fractures, allowing the gas or oil to flow more easily. The chemicals used in the fluid serve various purposes, such as reducing friction, preventing bacterial growth, and enhancing the overall efficiency of the process.

-

Fracture Creation: The pressurized fluid causes the rock formation to crack, creating fractures that extend into the surrounding rock. The proppant particles, mainly sand, are deposited into the fractures, holding them open after the pressure is released. This allows the gas or oil to flow through the fractures and into the wellbore.

-

Fluid Recovery and Well Production: After the fracturing process is complete, the pressure is reduced, and the fracturing fluid, along with the released gas or oil, flows back to the surface. The recovered fluids are treated and disposed of properly, while the gas or oil is collected for further processing and distribution.

Benefits and Controversies: Hydraulic fracturing has revolutionized the energy industry by enabling access to previously untapped reserves of natural gas and oil. It has the potential to boost energy production, enhance energy security, and stimulate economic growth. However, fracking is not without its controversies. Concerns have been raised about potential environmental impacts, including groundwater contamination, air pollution, induced seismic activity (earthquakes), and the disposal of wastewater. Regulations and industry best practices have been implemented to mitigate these risks and ensure safe operations.

A well is drilled vertically into the ground, typically reaching thousands of feet below the surface. Once the desired depth is reached, the drill bit is redirected horizontally to access a larger area of the underground reservoir.

-

-

Well Casing and Cementing: Steel casing is inserted into the well, and cement is then pumped into the space between the casing and the surrounding rock formations. This helps to secure the well and prevent any potential contamination of groundwater.

-

Fracturing Fluid Injection: A mixture of water, sand (proppant), and chemicals is pumped into the well at high pressure. The water acts as the main carrier, while the sand props open the fractures, allowing the gas or oil to flow more easily. The chemicals used in the fluid serve various purposes, such as reducing friction, preventing bacterial growth, and enhancing the overall efficiency of the process.

-

Fracture Creation: The pressurized fluid causes the rock formation to crack, creating fractures that extend into the surrounding rock. The proppant particles, mainly sand, are deposited into the fractures, holding them open after the pressure is released. This allows the gas or oil to flow through the fractures and into the wellbore.

-

Fluid Recovery and Well Production: After the fracturing process is complete, the pressure is reduced, and the fracturing fluid, along with the released gas or oil, flows back to the surface. The recovered fluids are treated and disposed of properly, while the gas or oil is collected for further processing and distribution.

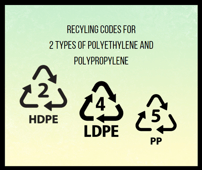

Types of Plastic Sheeting Tarps Used in Hydraulic Fracturing (fracking)

Several types of plastic sheeting tarps can be used in hydraulic fracturing (fracking) operations to serve different purposes. Here are some common types:

-

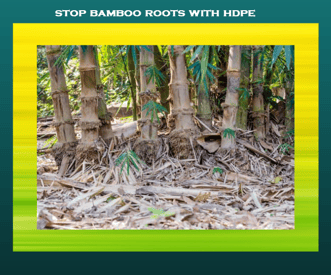

High-Density Polyethylene (HDPE) Tarps: HDPE tarps are widely used in fracking sites due to their durability and resistance to punctures and tears. They are commonly used to cover and protect equipment, materials, and stored items from exposure to the elements, such as rain, wind, and sunlight.

-

Polypropylene (PP) Tarps: PP tarps are lightweight, flexible, and resistant to chemicals, making them suitable for various applications in fracking operations. They are often used to cover frac tanks, containment ponds, and other storage areas to prevent leaks, spills, and contamination.

-

Reinforced Polyethylene (RPE) Tarps: RPE tarps are made with a combination of polyethylene and reinforcing materials, such as scrim or mesh, which enhance their strength and tear resistance. These tarps are commonly used as liners for frac pits, containment ponds, and secondary containment areas to prevent leaks and seepage of fluids.

-

PVC Tarps: PVC (Polyvinyl Chloride) tarps are known for their excellent chemical resistance and durability. They are commonly used in fracking sites for covering equipment, machinery, and storage areas, providing protection against weather elements and potential spills.

-

Fire-Retardant Tarps: In certain situations, fire-retardant tarps may be required to ensure safety in fracking operations. These tarps are designed to resist ignition and slow down the spread of flames, providing an added layer of protection in case of fire incidents.

It's important to note that the specific type of plastic sheeting tarp used in hydraulic fracturing can vary based on the specific needs and regulations of each site. Factors such as the type of fluid being stored or contained, environmental considerations, and local regulations will influence the choice of plastic sheeting material. It is crucial to select tarps that meet the necessary strength, durability, chemical resistance, and fire safety requirements for the intended application in the fracking process.

Benefits and Controversies: Hydraulic fracturing has revolutionized the energy industry by enabling access to previously untapped reserves of natural gas and oil. It has the potential to boost energy production, enhance energy security, and stimulate economic growth. However, fracking is not without its controversies. Concerns have been raised about potential environmental impacts, including groundwater contamination, air pollution, induced seismic activity (earthquakes), and the disposal of wastewater. Regulations and industry best practices have been implemented to mitigate these risks and ensure safe operations.

Conclusion: Hydraulic fracturing is a complex process that has significantly impacted the global energy landscape. By creating fractures in rock formations deep underground, it allows for the extraction of natural gas and oil that was previously inaccessible. While fracking offers numerous benefits in terms of energy production, it is crucial to carefully manage and address the environmental and safety considerations associated with the process.