What is Textured LLDPE?

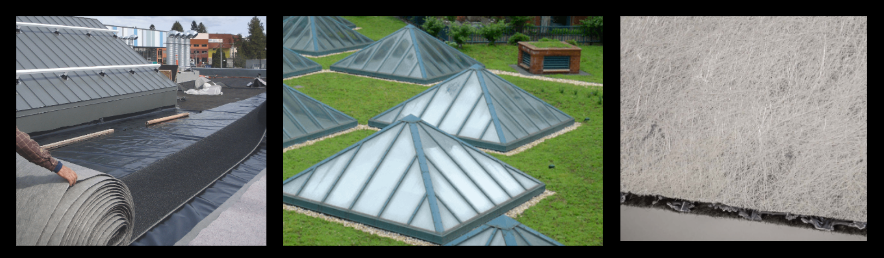

Low-density polyethylene (LLDPE) is a type of thermoplastic polymer renowned for its durability, flexibility, and resistance to chemicals and impact. Textured LLDPE refers to LLDPE sheets with a textured surface, providing enhanced grip and traction.

What is textured LLDPE made of?

LLDPE is derived from the polymerization of ethylene under specific conditions, resulting in a polymer with unique properties. Textured LLDPE is manufactured by extruding LLDPE resin through specialized machinery that imparts a textured pattern onto the surface.

Textured LLDPE Applications:

Textured LLDPE finds extensive applications across various industries due to its versatility and durability. Common uses include:

-

Landfills: Textured LLDPE liners are employed to contain and isolate waste materials, preventing leachate contamination and environmental hazards.

-

Reserve Pits: In oil and gas operations, reserve pits utilize textured LLDPE liners to contain drilling fluids and prevent soil contamination.

-

Frac Pits: During hydraulic fracturing processes, frac pits utilize textured LLDPE liners to contain fluids and chemicals, ensuring environmental safety and regulatory compliance.

-

Under Rig Liners: These liners provide a protective barrier beneath drilling rigs, preventing soil and groundwater contamination from drilling operations.

-

Retention Ponds: Textured LLDPE liners are used in retention ponds to contain stormwater runoff, preventing soil erosion and water pollution.

-

Fresh Water Pits: Textured LLDPE liners ensure the containment of fresh water reserves in agricultural or industrial settings, safeguarding against contamination.

-

Flowback Pits: In oil and gas production, flowback pits utilize textured LLDPE liners to contain and manage the flowback fluids, ensuring environmental protection.

-

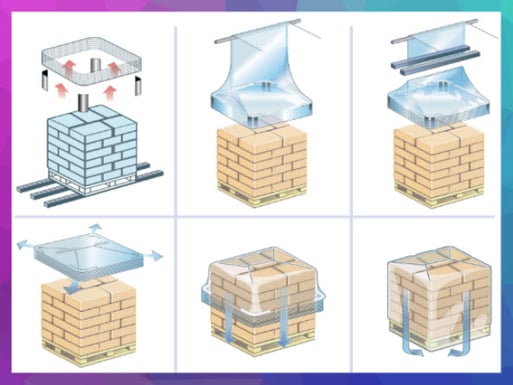

Secondary Containments: Textured LLDPE liners serve as secondary containment barriers for hazardous materials and liquids, preventing leaks and spills.

Who uses it?

Various industries rely on textured LLDPE for containment solutions, including:

- Oil and Gas

- Construction

- Waste Management

- Agriculture

- Environmental Engineering

- Manufacturing

When is it used?

Textured LLDPE is employed whenever there is a need for robust containment and protection against chemical exposure, impact, and environmental factors. It is utilized during initial construction phases and remains in place throughout the operation of facilities such as landfills, drilling sites, and retention ponds.

Textured LLDPE thicknesses:

Yes, textured LLDPE is available in various thicknesses to accommodate specific application requirements. Common thickness options range from 20 mil (0.5 mm) to 80 mil (2.0 mm) or higher, depending on the level of durability and protection needed for a particular application.

Why Textured LLDPE over HDPE?

While both LLDPE and high-density polyethylene (HDPE) offer excellent chemical resistance and durability, textured LLDPE provides additional benefits:

-

Enhanced Traction: The textured surface of LLDPE offers improved traction, making it suitable for applications where slip resistance is crucial, such as frac pits and retention ponds.

-

Flexibility: LLDPE is more flexible than HDPE, allowing for easier installation around irregular surfaces and contours, enhancing the overall effectiveness of containment systems.

-

Impact Resistance: Textured LLDPE exhibits superior impact resistance compared to smooth HDPE, reducing the risk of punctures or tears in demanding environments like construction sites and landfills.

-

Cost-Effectiveness: Textured LLDPE often proves to be a more cost-effective solution due to its lower material and installation costs compared to HDPE, making it an attractive option for various containment applications.

In conclusion, textured LLDPE offers a versatile and reliable solution for a wide range of containment needs across multiple industries. Its unique properties, including enhanced traction, flexibility, and impact resistance, make it a preferred choice for applications where durability and environmental protection are paramount.

Visit the Textured LLDPE Product Page here for more information and specifications.