Roadmap to Crawl Space Protection in the Heart of Atlanta

Atlanta, our beloved city in the heart of Georgia, is known for its vibrant culture, Southern charm, and, yes, its unique climate challenges. With hot, humid summers and the prevalence of crawl spaces in our homes, Atlanta homeowners face specific issues that demand a tailored approach to crawl space protection.

Table of Contents:

Introduction Welcome to the Atlanta Edition of The Ultimate Guide to Crawl Space Vapor Barriers. In this guide, we'll delve into the significance of crawl space vapor barriers in Atlanta's climate and how to select the right thickness.

The Importance of Crawl Space Vapor Barriers Discover why crawl space vapor barriers are crucial in Atlanta, protecting your home from moisture-related issues, pests, and radon.

Seeking Professional Guidance Navigating Atlanta's crawl space challenges requires expertise. Learn why consulting professionals is a wise choice.

Selecting the Right Thickness: Striking the Right Balance - Thickness and ASTM E1745 Compliance for Atlanta homes.

Thicker is Smarter: Why Invest in a Thicker Crawl Space Liner Delve into the advantages of thicker options, especially the 20 Mil String Reinforced Liner, tailored to Atlanta's needs.

Long-Term Reliability: Doing the Job Right the First Time Learn why durability matters in Atlanta's crawl spaces and how the right liner can protect your investment.

Radon Blocking Capabilities Understand how a quality crawl space liner can help combat the radon threat in Atlanta homes.

The Critical Role of Crawl Space Liner Materials Explore the significance of high-grade materials in ensuring long-term reliability.

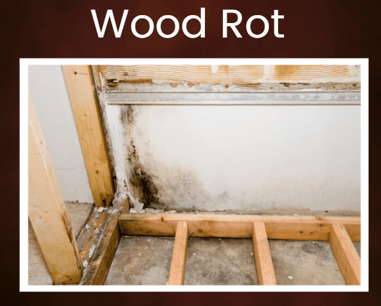

Ensuring Longevity: Life-Span of the Vapor Barrier Discover the dangers of sub-par materials and the importance of resisting decay and moisture attack.

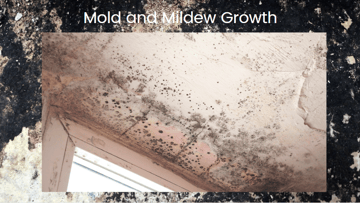

Addressing Challenges in Dirt Floor Crawl Spaces Learn how to tackle specific challenges in Atlanta's crawl spaces, from mold and mildew to unwanted pests.

Conclusion: Making Informed Decisions Equip yourself with the knowledge needed to protect your Atlanta home with the right crawl space vapor barrier.

If you'd like to receive the E-book version of The Ultimate Guide to Crawl Space Vapor Barriers: Atlanta Edition, simply click the button or fill out the form below and comment "E-Book for Crawl Space." Thanks for joining us on this journey to safeguarding your Atlanta home.