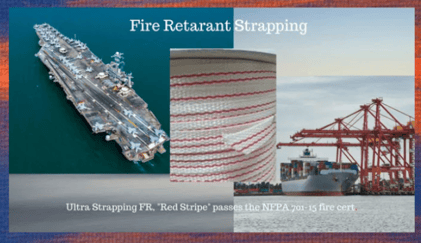

Introducing Ultra Strapping FR - "Red Stripe" Safety Strapping

In the ever-evolving world of strapping materials, one name stands out - Ultra Strapping FR, also known as "Red Stripe" Safety Strapping FR. This remarkable innovation has not only redefined load containment but has also passed the stringent NFPA 701-23 fire test with flying colors. Let's delve into the world of Ultra Strapping FR and discover why it's a game-changer in the industry.

NFPA 701-23 Fire Test: Setting the Standard

When it comes to fire safety, compliance with industry standards is essential. Ultra Strapping FR, often referred to as "Red Stripe" Safety Strapping FR, has successfully passed the NFPA 701-23 fire test. This certification sets the standard for fire-resistant strapping materials, ensuring that your loads are not only secure but also protected in case of fire-related emergencies.

Safety Meets Versatility

Ultra Strapping FR offers the perfect blend of safety and versatility. It's not just a strapping material; it's a safety solution. With its ability to withstand the NFPA 701-23 fire test, it becomes an invaluable asset in environments where fire safety is paramount. This strapping material is engineered to provide superior load containment, ensuring that your products stay secure during transit.

Applications Across Industries

The applications of Ultra Strapping FR are as diverse as the industries it serves. Whether you're in construction, manufacturing, or logistics, this safety strapping is a game-changer. It can be used for bundling and packaging materials, securing scaffolding and structures, and ensuring fire-resistant containment during transportation.

Customization for Your Brand

Just like its predecessor, Ultra Strapping FR - "Red Stripe" Safety Strapping FR can be customized with your company name or logo. This branding not only adds a professional touch to your packaging but also reinforces your commitment to safety and quality.

Eco-Friendly and Cost-Efficient

In addition to its fire-resistant properties, Ultra Strapping FR is environmentally friendly and easy to dispose of. It won't corrode or damage your products, making it an eco-conscious choice. Moreover, its lightweight design translates into cost savings on shipping and handling, making it a cost-effective solution for load containment.

Embracing Innovation and Safety

Ultra Strapping FR - "Red Stripe" Safety Strapping FR has set a new benchmark in the strapping industry. With its NFPA 701-23 fire test certification, it has become the preferred choice for industries that prioritize safety and reliability. Its ability to provide superior load containment, ensure fire safety, and offer eco-friendly disposal options has made it a revolutionary product in the world of strapping materials.

In conclusion, Ultra Strapping FR - "Red Stripe" Safety Strapping FR is the epitome of innovation and safety. Whether you're in the construction sector, manufacturing industry, or any field requiring load containment, consider making the switch to this fire-resistant strapping material. Say goodbye to compromise and embrace the future of strapping technology with Ultra Strapping FR - a safety solution that goes above and beyond.