Navigating Vapor Barriers: A Comprehensive Guide to Dos and Don'ts

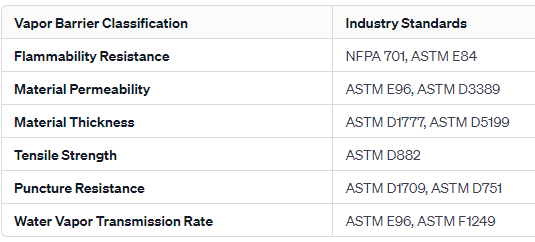

In the realm of construction and environmental protection, vapor barriers play a crucial role in maintaining structural integrity and ensuring the longevity of buildings. Understanding the dos and don'ts of vapor barriers is essential for architects, builders, and homeowners alike. In this comprehensive guide, we'll delve into the intricacies of vapor barriers, discussing best practices, standards such as NFPA 701 and ASTM E84, and pitfalls to avoid.

What is a Vapor Barrier?

A vapor barrier is a material designed to impede the transmission of water vapor, preventing moisture from infiltrating building structures. It is a critical component in controlling humidity levels and safeguarding against potential issues like mold growth and structural damage.

Dos:

1. Choose the Right Material:

Selecting an appropriate vapor barrier material is paramount. Materials that comply with industry standards such as NFPA 701 (National Fire Protection Association) and ASTM E84 (American Society for Testing and Materials) ensure safety and performance.

2. Consider Location and Climate:

Tailor the choice of vapor barrier to the specific climate and location of the building. A vapor barrier that works effectively in a humid climate may not be suitable for a drier region.

3. Proper Installation:

Ensure meticulous installation by following manufacturer guidelines. Proper sealing of seams and overlaps is crucial to the barrier's effectiveness.

4. Integrate with Building Design:

Incorporate vapor barriers seamlessly into the overall building design. Consider factors such as insulation and ventilation to create a comprehensive moisture control strategy.

5. Regular Inspections:

Periodically inspect the vapor barrier to identify any signs of damage or deterioration. Address issues promptly to maintain the barrier's integrity.

Don'ts:

1. Ignoring Standards:

Neglecting adherence to industry standards, such as NFPA 701 and ASTM E84, can compromise safety and performance. Always verify that the chosen vapor barrier meets or exceeds these standards.

2. Overlooking Permeability:

Failing to account for the permeability of the vapor barrier material can lead to moisture entrapment. Choose materials with appropriate permeability levels based on the specific application.

3. Incomplete Sealing:

Inadequate sealing of seams and overlaps can result in moisture infiltration. Thoroughly seal all joints to maintain the barrier's effectiveness.

4. Improper Storage:

Mishandling or storing vapor barrier materials inappropriately can affect their performance. Follow manufacturer guidelines for storage to prevent damage.

5. Neglecting Building Codes:

Disregarding local building codes and regulations regarding vapor barriers can result in legal and structural complications. Always ensure compliance with relevant codes.

Industry Standards: NFPA 701 and ASTM E84

1. NFPA 701:

NFPA 701 outlines standards for the flammability of textiles used in interior furnishings and draperies. Choosing a vapor barrier that complies with NFPA 701 ensures fire safety within the building envelope.

2. ASTM E84:

ASTM E84, also known as the Steiner Tunnel Test, assesses the surface burning characteristics of building materials. Vapor barriers adhering to ASTM E84 standards demonstrate their fire resistance, helping in creating safer environments.

Conclusion:

Navigating the complexities of vapor barriers requires a keen understanding of material properties, climate considerations, and adherence to industry standards. By following the dos and don'ts outlined in this guide and prioritizing compliance with standards like NFPA 701 and ASTM E84, stakeholders can ensure effective moisture control and a safer, more durable building envelope. Stay informed, choose wisely, and build with confidence.

Visit the Vapor Barrier Product Page here