All About Tank Liners

Ever wondered how those massive storage tanks, holding everything from water to chemicals, maintain their integrity and prevent leaks? The answer lies in the silent guardians within – tank liners. These heavy-duty barriers play a crucial role in safeguarding both the environment and the materials stored inside tanks.

Why Line Tanks?

Tanks, despite their robust construction, can experience wear and tear over time, making them susceptible to:

- Corrosion: External factors like weather and internal contents can cause the tank material to degrade, leading to leaks and potential environmental contamination.

- Punctures: Accidental damage during installation, filling, or maintenance can compromise the tank's integrity.

- Permeability: Some tank materials, like concrete, can be slightly porous, allowing for slow leakage of the stored content.

The Lining Solution:

Tank liners act as an impermeable barrier between the stored material and the tank wall, offering several benefits:

- Leak prevention: They prevent leaks caused by corrosion, punctures, or even slight permeability of the tank material.

- Content protection: Liners safeguard the stored material from contamination by external elements.

- Corrosion resistance: They shield the tank walls from the corrosive effects of the stored contents, extending the tank's lifespan.

- Easier cleaning: Smooth liner surfaces make cleaning and maintenance simpler and more efficient.

Types of Tank Liners:

The choice of liner material depends on various factors like the type of liquid being stored, temperature requirements, and budget. Here are some common options:

- High-Density Polyethylene (HDPE): This versatile and cost-effective option offers good chemical resistance and is suitable for water, wastewater, and some mild chemicals.

- Vinyl Ester: Known for its exceptional chemical resistance, vinyl ester liners are ideal for storing aggressive chemicals and hydrocarbons.

- Epoxy: Offering superior adhesion and chemical resistance, epoxy liners are well-suited for highly corrosive environments and can withstand a wider temperature range.

- Polypropylene (PP): This lightweight and cost-effective option is often used for storing food-grade liquids and is resistant to many chemicals.

Applications of Tank Liners:

Tank liners find applications in various industries, including:

- Water treatment: They line water tanks, reservoirs, and treatment ponds to prevent contamination and ensure clean water storage.

- Wastewater treatment: Liners play a crucial role in wastewater treatment facilities, preventing leaks and protecting the environment.

- Chemical storage: Tanks used for storing chemicals like acids, alkalis, and solvents rely on liners for safe and leak-proof containment.

- Oil and gas industry: Liners are essential for secondary containment in oil and gas exploration and storage facilities to prevent environmental damage in case of spills or leaks.

- Agriculture: Liners are used in agricultural applications like manure storage pits and irrigation ponds to prevent contamination of soil and groundwater.

The GPS Tank Liner:

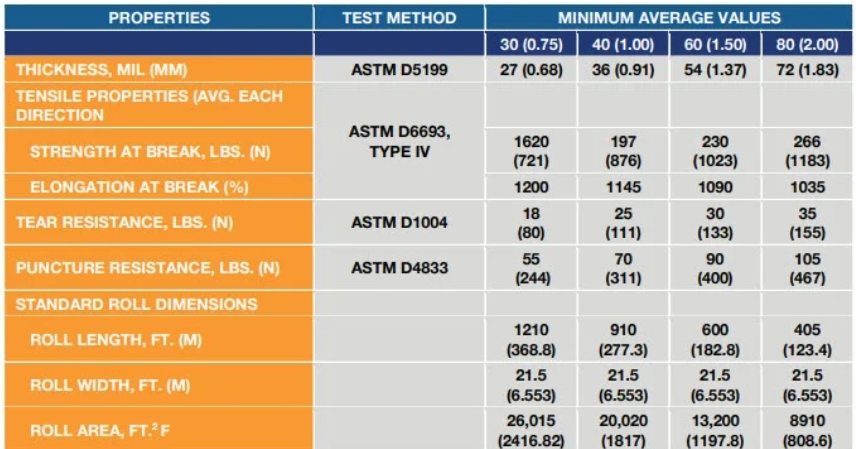

GPS offers custom-fabricated HDPE liners. These liners are known for their:

- Puncture resistance and elongation: They can withstand accidental punctures and maintain their shape even under stress.

- Leak-proof performance: Made from high-quality materials in the USA, they ensure reliable leak prevention.

- Single-piece fabrication: Large, single-piece liners eliminate the need for on-site seaming, simplifying installation and reducing potential leak points.

- Customization: Available in standard sizes or custom-made, they can fit various tank configurations.

Lifespan of Tank Liners:

The lifespan of a tank liner depends on several factors, including:

- Liner material: Different materials have varying lifespans depending on their inherent properties and resistance to degradation.

- Stored materials: Aggressive chemicals can degrade liners faster than neutral liquids.

- Environmental conditions: Exposure to UV radiation and extreme temperatures can shorten the lifespan.

- Installation and maintenance: Proper installation and regular inspections are crucial for maximizing the liner's lifespan.

Generally, well-maintained tank liners can last 10 to 20 years or even longer, depending on the factors mentioned above.

By understanding the purpose, types, and applications of tank liners, we gain appreciation for these silent guardians that ensure safe and responsible storage of various liquids, contributing to environmental protection and efficient operations across diverse industries.