Fluted Polypropylene Sheets: A Versatile and Fire-Safe Alternative

Fluted polypropylene sheets, often called "plastic cardboard" or corrugated boards are a popular choice for a variety of applications. They offer several advantages over traditional materials like wood or cardboard, making them a versatile and cost-effective alternative. Here's a closer look at why you should consider fluted polypropylene sheets for your next project:

What are Fluted Polypropylene Sheets?

These sheets are lightweight, durable panels made from polypropylene plastic. They feature a unique fluted core, creating a strong and rigid structure despite their low weight. This design also provides excellent insulation properties.

Key Benefits:

- Fire Retardant: The biggest advantage of the specific product discussed in this blog is its fire-resistant properties. It passes several key fire safety standards, including UL 94 V-0, indicating it has the highest flame retardancy rating. This makes it a great choice for applications where fire safety is a major concern.

- Durable: Fluted polypropylene sheets are highly resistant to impact, tearing, and chemicals. They won't crack or split easily, making them ideal for demanding environments.

- Lightweight: These sheets are significantly lighter than wood or plywood, making them easier to transport, handle, and install.

- Waterproof and Moisture Resistant: Fluted polypropylene won't warp or rot when exposed to moisture, making it suitable for outdoor use or applications involving water.

- Cost-Effective: Compared to traditional building materials like plywood, fluted polypropylene sheets offer a cost-effective solution.

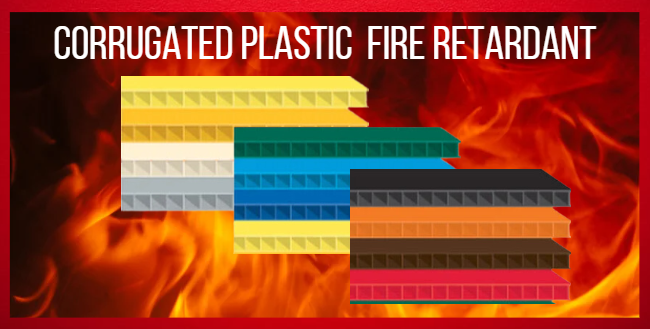

- Versatility: These sheets come in a variety of thicknesses, sizes, and even colors. They can be easily cut, drilled, and shaped to fit your specific needs.

- Eco-Friendly: Fluted polypropylene sheets are 100% recyclable, making them an environmentally friendly choice.

Applications:

Fluted polypropylene sheets have a wide range of applications across various industries. Here are some examples:

- Construction: Use them for temporary walls, floor protection, signage, and concrete curing.

- Signage and Displays: Their lightweight nature and printability make them ideal for temporary signs and displays.

- Packaging: These sheets can be used for protective packaging for delicate items during shipping.

- Events and Exhibits: Create dividers, booths, and displays for trade shows or events.

- Agricultural Applications: Use them for greenhouses, crop protection, and signage.

Fire Safety Ratings Explained:

NFPA 701-2015 (National Fire Protection Association 701):

- Focuses on flame propagation: This standard assesses how quickly flames will spread across a material's surface under controlled laboratory conditions.

- Used for: Textiles, films, and other flexible materials commonly used in building interiors like curtains, upholstery, and some plastic films.

- Importance: Helps determine a material's suitability for specific applications in a building based on its ability to resist flame spread and contribute to a fire's growth.

ASTM E-84-18A (American Society for Testing and Materials E-84):

- Measures surface burning characteristics: This widely used standard evaluates a material's flame spread and smoke development when exposed to a fire source in a controlled tunnel test.

- Used for: Exposed interior building materials like wall and ceiling finishes, including panels, tiles, and some plastic sheets.

- Importance: Helps classify materials based on their contribution to a fire's growth and smoke generation within a building, influencing decisions about suitable materials for specific locations.

UL 94 (Underwriters Laboratories 94):

- Evaluates flammability of plastic materials: This standard focuses on the burning behavior of plastic components used in electronics and appliances.

- Uses different test methods (HB, V-0, V-1, V-2): These methods subject plastic samples to a small flame source and evaluate their burning behavior, including self-extinguishing properties, burning time, and dripping.

- HB (Horizontal Burn): Material self-extinguishes after a set time in a horizontal orientation. (Least flame retardant)

- V-2 (Vertical Burn): Material self-extinguishes within 60 seconds in a vertical orientation, with flaming drips allowed.

- V-1 (Vertical Burn): Material self-extinguishes within 60 seconds in a vertical orientation, with NO flaming drips allowed.

- V-0 (Vertical Burn): Material self-extinguishes within 10 seconds in a vertical orientation, with NO flaming drips allowed. (Most flame retardant)

- Importance: Helps ensure the plastic components in electronic devices and appliances have appropriate fire resistance properties, minimizing fire risks associated with electrical malfunctions.

In summary, these standards all play a role in fire safety by evaluating the flammability of various materials used in construction and building products. They help architects, builders, and code officials make informed decisions about which materials are suitable for specific applications, contributing to overall fire safety in buildings.

In Conclusion:

Fluted polypropylene sheets offer a compelling alternative to traditional materials. Their combination of affordability, durability, fire resistance, and versatility makes them a valuable tool for various applications. Consider incorporating them into your next project for a lightweight, cost-effective, and fire-safe solution.