Beyond the Mil: Choosing the Right Flexible Plastic Sheeting for Your Project

In the world of DIY projects and industrial applications, flexible plastic sheeting reigns supreme. From drop cloths protecting your freshly painted masterpiece to greenhouse covers nurturing your prized vegetables, its versatility is undeniable. But when it comes to choosing the right plastic sheeting, thickness, often measured in mils (1 mil = 1/1000 of an inch), is just the tip of the iceberg.

This guide dives deep into the factors beyond mil thickness that influence your plastic sheeting selection. By understanding these factors, you can ensure your chosen sheeting delivers optimal performance for your specific project.

The Power of Plastic:

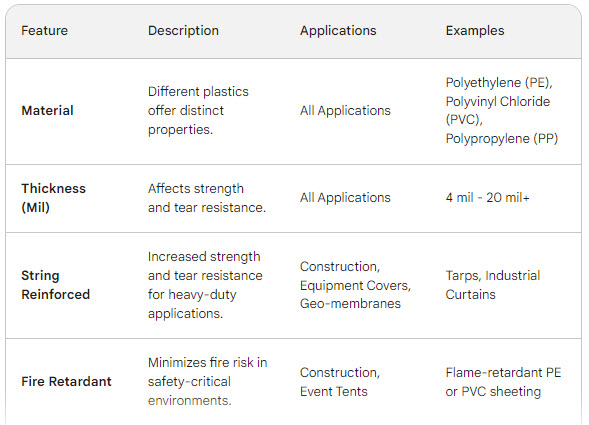

Flexible plastic sheeting comes in a myriad of materials, each with its own strengths and weaknesses. Here are some common types you'll encounter:

- Polyethylene (PE): The ever-reliable workhorse, PE offers a good balance of affordability, clarity, and water resistance. It's available in a wide range of thicknesses, making it suitable for various applications.

- Polyvinyl Chloride (PVC): Known for its durability and tear resistance, PVC is a popular choice for heavy-duty projects. It's often treated for UV resistance and can withstand harsh weather conditions.

- Polypropylene (PP): Offering excellent chemical resistance and high melting point, PP is ideal for projects involving solvents or hot objects.

Beyond Plastic Sheeting Thickness: A Multifaceted Choice

While mil thickness provides a basic understanding of a plastic sheet's strength, here are the other crucial factors to consider:

- Material Properties: As mentioned earlier, different plastics have distinct properties. Understanding these properties is essential for selecting the right material for your project's needs.

- Strength and Tear Resistance: Consider the potential stress the sheeting will encounter. For tasks involving sharp objects or heavy loads, prioritize high tear resistance.

- Chemical Resistance: Will your project involve exposure to chemicals, solvents, or oils? Choose a plastic specifically formulated for such environments, like PP.

- Temperature Resistance: Projects involving extreme temperatures require sheeting that can withstand them. PE has a lower melting point than PVC, which makes it unsuitable for high-heat applications.

- Light Transmission: This is particularly important for applications like greenhouses or grow tents. Look for sheeting with high light transmission to ensure optimal plant growth. Diffused light options can also be beneficial to prevent hot spots and scorching.

- Fire Retardancy: For safety-critical applications, select flame-retardant plastic sheeting to minimize fire risk.

- UV Resistance: Standard plastic sheeting degrades under sunlight exposure. If your project requires prolonged outdoor use, opt for UV-treated sheeting for extended lifespan.

- Durability: Consider the lifespan requirement for your project. Some sheeting types, like heavy-duty PVC, offer superior durability compared to standard PE.

- Weight and Flexibility: Lighter weight sheeting is easier to handle but might offer less strength. Conversely, heavier sheeting can be more challenging to manipulate but provides greater durability.

Special Considerations:

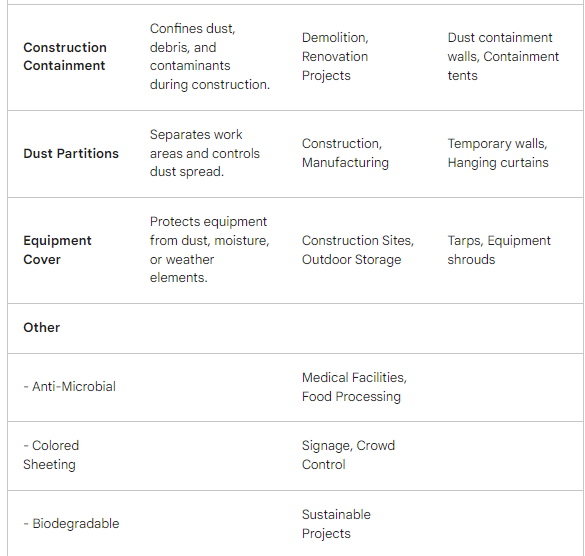

- Color: Colored sheeting can offer benefits depending on the application. Black sheeting can block sunlight, while white sheeting can reflect heat.

- Anti-Static Properties: Electrostatic buildup can be a concern in certain environments. Consider anti-static sheeting to mitigate this issue.

- Environmental Impact: If sustainability is a priority, look for sheeting made from recycled materials or with a focus on biodegradability.

Making the Perfect Match:

Now that you understand the various factors at play, here's how to translate this knowledge into selecting the right sheeting:

- Clearly Define Your Project: Understand the specific purpose and environment where you'll be using the sheeting.

- Prioritize Your Needs: Identify which properties (strength, UV resistance, light transmission) are most crucial for your project.

- Evaluate Materials: Research different plastic types and their properties to find one that aligns with your needs.

- Consider Thickness: While not the sole factor, mil thickness plays a role in strength and tear resistance. Choose a thickness that provides adequate support for your project's demands.

- Compare Options: Explore various brands and retailers to find the best combination of features and price.

Beyond the Basics:

For specific applications, specialized plastic sheeting options exist:

- Drop Cloths: These typically use heavier PE for protection against paint spills and debris.

- Weed Barrier Fabric: Often woven from polypropylene, this material allows water to pass through while suppressing weed growth.

- Vapor Barrier: This plastic film acts as a moisture barrier in construction projects, often using materials like HDPE (High-Density Polyethylene).

Get Expert Advice!

Remember: Don't hesitate to seek help from Global Plastic Sheeting (866.597.9298) who sells to world wide project managers on the daily. They can offervaluable guidance based on your specific project requirements and the available product options.

Conclusion:

Choosing the right plastic sheeting goes beyond simply grabbing the thickest option available. By understanding the various factors at play, from material properties to specific project needs, you can make an informed decision. Remember, the perfect sheeting is the one that strikes the perfect balance between functionality, durability, and cost-effectiveness for your unique project. So, the next time you reach for plastic sheeting, remember – it's more than just a sheet, it's a partner in bringing your project to life!