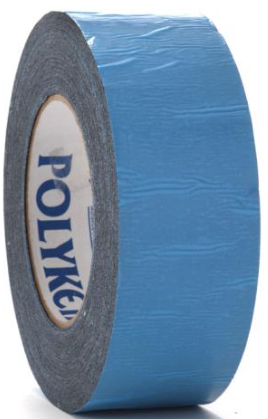

Polyken 108FR tape is not your average adhesive tape; it's a versatile solution with a wide range of applications and benefits. Let's delve into the depths of this remarkable tape and explore where and why it excels beyond the conventional.

Fire Retardant Tape: Applications Beyond the Norm:

-

Aircraft Carpet Installation: Polyken 108FR is trusted for securing carpeting on aircraft floors and stairs, providing a reliable hold in high-traffic areas without compromising safety or aesthetics.

-

Acrylic Sheeting Sealing: Whether in aviation or architectural projects, this tape effectively hangs and seals acrylic plastic sheeting, ensuring a durable bond that withstands varying environmental conditions.

-

Machine Shop Applications: From mounting components to securing equipment, Polyken 108FR excels in machine shop environments, offering a strong, yet removable adhesive solution for diverse industrial needs.

-

Aviation Industry Endorsement: With endorsements from industry giants like Boeing, Lockheed, and Douglas, as well as major airlines and refurbishers, Polyken 108FR is a trusted choice for critical aerospace applications.

Features & Benefits:

- Cloth Reinforcement: The tape's cloth reinforcement provides added strength and elongation, facilitating easy tear, application, and removal for enhanced efficiency.

- Flame Retardant Adhesive: Equipped with a flame retardant rubber-based adhesive, Polyken 108FR ensures safety in environments where fire resistance is paramount.

- Clean Removal: Despite its strong bond, this tape offers clean removal from most surfaces, leaving minimal residue and reducing cleanup efforts.

- Repositionable Adhesive: Its repositionable adhesive feature allows for easy installation and adjustments, ensuring precise placement without sacrificing bond strength.

OEM & Specification Compliance: Polyken 108FR meets stringent industry standards and specifications, including those set by Boeing, Lockheed, FAA, and other regulatory bodies, ensuring reliability and compliance in critical applications.

Versatility Beyond Expectation: While Polyken 108FR excels in aerospace and industrial settings, its versatility extends beyond. From home improvement projects requiring secure bonding to museum installations demanding preservation-grade sealing, and even haunted house constructions necessitating flame-retardant materials, this tape proves indispensable.

Questions About Fire Retardant Tape:

1. What is fire retardant tape and how does it work?

Fire retardant tape is a specialized adhesive tape treated with chemicals that help slow the spread of fire. It works by forming a char barrier when exposed to high temperatures, which insulates the underlying material and delays ignition of nearby combustibles.

2. What are the different types of fire retardant tape?

There are several types of fire retardant tape available, each with its own specific properties and applications. Common types include:

- Acrylic: Offers good adhesion and flexibility, commonly used for indoor applications like sealing cable openings.

- Silicone: High-temperature resistance, often used for sealing ducts and other high-heat areas.

- Ceramic: Exceptional fire resistance, ideal for critical applications like electrical panels and fire doors.

- Intumescent: Expands under heat, creating a thick char barrier, suitable for sealing gaps and joints.

3. Where can I use fire retardant tape?

Fire retardant tape has a wide range of applications, including:

- Sealing gaps and joints around electrical cables, pipes, and ducts.

- Creating temporary fire barriers in construction zones.

- Repairing minor damage on fire-rated walls and doors.

- Securing thermal insulation in high-temperature environments.

4. Is fire retardant tape enough to fireproof something?

No, fire retardant tape is not a substitute for proper fireproofing materials and building codes. It's a supplementary measure that can buy time in case of fire, but it won't prevent combustion forever. Always consult building regulations and fire safety professionals for appropriate fireproofing solutions.

5. What are the safety precautions when using fire retardant tape?

- Ensure the surface is clean and dry before applying the tape.

- Apply the tape according to the manufacturer's instructions, ensuring proper overlap and coverage.

- Regularly inspect the tape for wear and tear and replace it when necessary.

Polyken 108 FR: Double-Coated Flame Retardant Carpet Tape

| Product Information | |

|---|---|

| Adhesive Type | Rubber |

| Carrier / Facestock | Cloth |

| Gauge / Mil | 15 mil |

| Liner Type | Film |

| Operating Temp Range | 40 to 200 °F |

| Color(s) | Natural, Black |

| Weight per Square Yard | 13 oz/sy |

Features & Benefits:

- Cloth reinforcement

- Good strength and elongation for easy tear, application, and removal

- Comfortable and moisture resistant

- Flame retardant rubber-based adhesive

- Clean removal from most surfaces

- Aggressive bond secure hold

- Repositionable adhesive for easy installation

Ideal For:

- Carpet installation on interior floors and stairs of aircraft

- Hanging and sealing acrylic plastic sheeting

- Mounting, bonding, and securing for general machine shop applications

Conclusion: Polyken 108FR tape is not just adhesive; it's a solution that transcends boundaries and exceeds expectations. With its unmatched performance, reliability, and versatility, it's the go-to choice for professionals across diverse industries and applications. Whether in the air, on the ground, or in your everyday projects, Polyken 108FR delivers where others fall short.