Enkadrain is a highly efficient drainage solution used in various construction and landscaping applications. Designed to manage water flow and prevent soil saturation, Enkadrain’s core technology utilizes a three-dimensional polymeric mat, which is encased in filter fabric. This unique construction allows for excellent water drainage, helping to protect building foundations, roadways, retaining walls, and more.

To understand how Enkadrain works, it’s important to consider its hydraulic conductivity, often expressed through the "K value." The K value measures how easily water can move through a material—higher K values indicate faster water movement, while lower K values suggest slower drainage.

Hydraulic Conductivity and Enkadrain Applications

The flow rate of Enkadrain products varies based on the type of soil they are applied in. Let's break down different scenarios where Enkadrain is used, considering the K values for specific soil types like silty sand and sandy clay.

1. Enkadrain Flow in Silty Sand (K Value: 0.33)

Characteristics of Silty Sand:

Silty sand is known for its relatively high permeability, meaning it allows water to drain through the soil more effectively. The K value of 0.33 for silty sand reflects its ability to conduct water efficiently, ensuring that excess water doesn’t accumulate at the surface or within the soil. This is important in scenarios where preventing waterlogging is crucial, such as beneath buildings or along highways.

Enkadrain Application in Silty Sand:

In areas with silty sand, Enkadrain is employed to optimize water drainage without compromising soil stability. The Enkadrain flow chart for silty sand, with a K value of 0.33, would focus on addressing the soil’s higher permeability. Enkadrain's drainage matting can efficiently channel water away from structures, protecting against the erosion or structural damage that can occur in these conditions.

2. Enkadrain Flow in Sandy Clay (K Value: 0.56)

Characteristics of Sandy Clay:

Sandy clay has a mix of sand and clay particles, resulting in a moderate to high permeability, depending on its composition. With a K value of 0.56, sandy clay demonstrates higher hydraulic conductivity compared to silty sand. This means water can move through sandy clay relatively easily, but its ability to retain water can vary.

Enkadrain Application in Sandy Clay:

For soils with a K value of 0.56, like sandy clay, Enkadrain solutions are designed to handle greater water flow. The Enkadrain matting ensures that water is efficiently moved away from the soil, preventing saturation while allowing enough moisture retention for the soil to maintain its structural integrity. This makes Enkadrain ideal for use under roadways, in sports fields, or around building foundations, where controlled drainage is essential for preventing flooding or erosion.

3. Enkadrain Flow in Sandy Clay (K Value: 0.42)

Characteristics of Sandy Clay:

Sandy clay with a K value of 0.42 represents a moderate level of water conductivity. In this case, the soil allows water to pass through at a moderate rate, which means that while water doesn’t pool at the surface, it also doesn’t drain too quickly.

Enkadrain Application in Sandy Clay with a K Value of 0.42:

In areas with moderate hydraulic conductivity like this, Enkadrain is used to create a balanced water management system. The matting’s design is able to handle moderate water flow, preventing soil from becoming oversaturated while ensuring that sufficient water is drained away from key areas. This application is particularly useful in landscaping projects, green roofs, and retaining walls, where controlled drainage is necessary to maintain soil stability.

Key Features of Enkadrain

-

Efficient Water Management:

Enkadrain’s three-dimensional design allows for superior water flow control. Its structure is capable of handling different levels of hydraulic conductivity across various soil types. -

Flexibility in Use:

Whether installed vertically or horizontally, Enkadrain is adaptable to many environments, including below concrete slabs, along embankments, and in road constructions. -

Erosion Control:

By guiding water away from critical areas, Enkadrain helps to prevent erosion in landscapes, retaining walls, and other outdoor structures. -

Environmentally Friendly:

Enkadrain products are often made from recycled materials and are designed to reduce the risk of flooding and structural water damage, which can result in long-term environmental benefits.

Enkadrain Applications

Enkadrain is widely used in construction and landscaping projects where water management is essential. Some common applications include:

-

Building Foundations:

Enkadrain is often installed around the perimeter of foundations to prevent water from accumulating and potentially damaging the structure. -

Road and Highway Construction:

The product can be installed beneath roadways to prevent water from pooling, which can lead to road damage or erosion. -

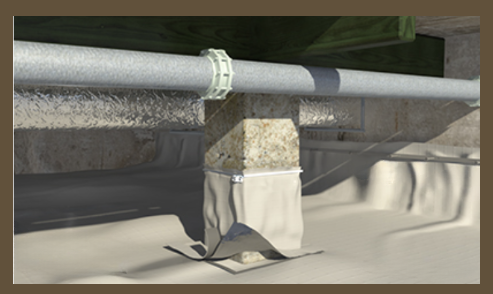

Retaining Walls:

Enkadrain’s ability to control water flow helps to prevent soil saturation behind retaining walls, reducing the risk of structural failure. -

Landscaping and Sports Fields:

Enkadrain is commonly used in green spaces to prevent waterlogging and maintain healthy, well-drained soils for optimal plant growth. -

Green Roofs:

In urban environments, Enkadrain is frequently used in green roof systems to ensure proper drainage while retaining enough moisture for plants.

How Enkadrain Contributes to Long-Term Durability

Enkadrain’s innovative design ensures the long-term stability of the structures it protects. By effectively managing water flow, the product helps to prevent the gradual wear and tear caused by excessive moisture or water pressure. This extends the life of building foundations, roadways, and landscapes, reducing maintenance costs over time.

Conclusion

Enkadrain provides a robust and versatile solution for managing water flow in a variety of settings. Its ability to adapt to different soil types, such as silty sand and sandy clay, ensures that it can be tailored to meet the specific needs of any construction or landscaping project. By utilizing Enkadrain, you can ensure that water is efficiently drained away from critical structures, reducing the risk of damage, erosion, and long-term environmental impact.