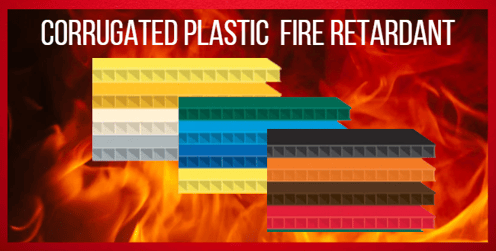

Corrugated Plastic Sheets: Unraveling the Multitude of Advantages

Introduction:

Corrugated plastic sheets, also known as fluted boards, corrugated boards/sheets, have become a staple in numerous applications due to their unique structure and exceptional properties. In this technical explanation, we'll delve into the essence of these twin-wall or multi-wall plastic sheets and explore the myriad of advantages they offer.

A Multitude of Advantages:

-

Strength-to-Weight Ratio: The corrugated design enhances the overall strength of the sheets while maintaining a lightweight profile. This makes them ideal for applications requiring structural integrity and reduced weight.

- Fire Resistant Properties: The FR versions Passes UL-94, NFPA 701-15 and ASTM E 84-18A

-

Impact Resistance: The corrugated structure bestows excellent impact resistance, making the sheets less susceptible to damage and deformation. They are perfect for protecting delicate items during transportation and handling.

-

Flexibility and Bending Resistance: Corrugated sheets exhibit flexibility and can bend without breaking, effortlessly conforming to curved surfaces or irregular shapes.

-

Insulating Properties: The air trapped within the corrugations provides effective insulation, making the sheets suitable for applications requiring thermal and electrical insulation.

-

Water Resistance: Corrugated plastic sheets, made from polypropylene or polyethylene, exhibit natural water and moisture resistance, making them perfect for outdoor and wet environments.

-

Chemical Resistance: These sheets showcase resistance to various chemicals, making them suitable for applications in corrosive environments.

-

Ease of Fabrication: Corrugated plastic sheets can be easily cut, scored, and folded, allowing for versatile customization and streamlined fabrication in diverse engineering projects.

Applications Across Industries:

Corrugated plastic sheets have found their niche in various industries due to their exceptional properties:

-

Agriculture: In agriculture, corrugated plastic sheets offer waterproof, recyclable, re-usable, and sturdy solutions for boxes and containers.

-

Automotive- Aerospace- Ship Building: The automotive industry leverages the fire retardant option, strength and lightweight nature of corrugated plastic sheets for durable and water-resistant applications.

-

Packaging: Highly valued in the packaging industry, these sheets are renowned for their design versatility, durability, waterproof features, and recyclability, making them perfect for product boxes.

-

Signage and Graphic Arts: From real estate signs to promotional banners, corrugated plastic sheets serve as the foundation for high-quality printable surfaces, withstanding rain and stains while ensuring reusability.

Conclusion:

Corrugated plastic sheets, available in a wide variety of colors and thicknesses, andflame retardancy are a reliable and versatile solution in heavy industry. Their ability to withstand impacts, resistance to water and chemicals, and ease of fabrication make them indispensable across an array of industries. Whether for packaging, signage, or agricultural applications, corrugated plastic sheets offer an amalgamation of qualities that redefine the standards of modern engineering materials.