EnkaVent ASV - Ventilation That Promotes Air Flow

Roofs can be one of the least energy-efficient components of the building envelope. 20% of electric energy use can be due, in warm months, to heat transfer from the roof to living areas below. Elevating the roof cover from the roof deck to promote above-sheathing ventilation is an effective solution to reducing heat gain in the attic. Combined with cool metal roofing panels Enkamat® ASV can reduce heat gain through the roof by 50% compared to a nailed asphalt shingle roof and with the added benefit of providing sound control from external sources such as rainfall.

Metal Roof Drainage and Ventilation

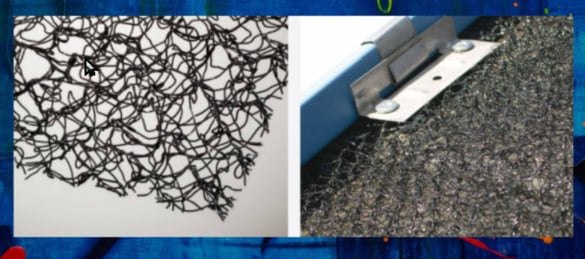

Stretch the lifespan of your roof with ventilation and drainage Metal roofing is inherently long-lived. Yet including Enkamat ASV can make it even more so by promoting free-flowing, multi-directional ventilation and drainage, reducing the likelihood of moisture-caused, roof compromising problems such as ice damming, mold, mildew, corrosion and rot in contrast to laying metal panels directly on the substrate or on furring strips creating channels that limit air and water flow to one direction. Patented Above-Sheathing Ventilation combats wasteful airspace With its unique, 95% open structure, Enkamat ASV creates an unbroken airspace, a highly effective thermal break between the metal roofing panels and sheathing yielding

Stretch the lifespan of your roof with ventilation and drainage Metal roofing is inherently long-lived. Yet including Enkamat ASV can make it even more so by promoting free-flowing, multi-directional ventilation and drainage, reducing the likelihood of moisture-caused, roof compromising problems such as ice damming, mold, mildew, corrosion and rot in contrast to laying metal panels directly on the substrate or on furring strips creating channels that limit air and water flow to one direction.

Patented Above-Sheathing Ventilation combats wasteful airspace

With its unique, 95% open structure, Enkamat ASV creates an unbroken airspace, a highly effective thermal break between the metal roofing panels and sheathing yielding significant energy-related benefits. Using Enkamat ASV lowers rooftop temperatures in warmer climates which in turn lower lifetime building cooling costs and reduces heat emitting into the surrounding air (the heat island effect). In colder climates the ventilation prevents moisture building up into ice dams.

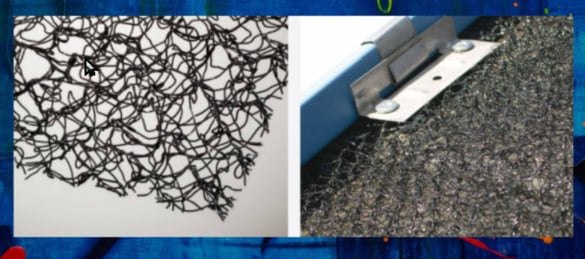

Faster fastening- Ease Of Installation

By supporting roof panels at all points from edge to edge, Enkamat ASV eliminates the time-consuming task of precisely placing each fastener to align with underlying, unseen furring strips. This speeds and eases installation, while creating a walkable, damage-resistant roof.

Enkavent ASV Properties

• Class A Fire Rating ASTME 84

• Recommended for use with Structural insulated Panels (SIP) • Suitable for steep slope applications

• Ideal for vertical (metal wall/sheathing) applications

• Lightweight, flexible conformable rolls

• Easy to cut with scissors or knife

• Protects weather barrier membrane during panel installation

• Acts as a slip sheet, allowing easy panel positioning

• Quickly and securely attaches with common fasteners

• Reduces rainfall noise up to 50%

EnkaMat®ASV 7010 Ventilation Solutions

EnkaMat®ASV 7010 is a 3-D multi-use mat, with continuous nylon filaments fused where they intersect. It can be used in metal and ballasted roofing applications where the spacing of the roof will provide the ventilation and drainage needed for a long service life. The nylon filaments do not fail under the load of the roof and the rigors of the construction environment, including heavy foot traffic. The space between the roof membrane/weather barrier underlayment and the ballast/metal roof allows moisture to flow away or evaporate. It is required under zinc roofs to prevent white rust caused by condensation on the underside of the roof. The use of EnkaMat®ASV 7010 as a thermal break creates a temperature difference of up to 22°F between the roof surface and the sheathing or substrate. The entangled filament structure also reduces impact noise from rain or sleet by 9.5 to 13.5 dB compared with a metal roof directly on the weather barrier. When combined with thermal insulation and a ceiling system noise levels are reduced up to 21 dB.

Applications

- Spacer between zinc and other metal roofs and the weather barrier underlayment or plywood substrate in sloped applications

- Thermal break between roofing materials and sheathing

- Spacer between ballast and loose laid, fully adhered or mechanically attached roofs

Features and Benefits

- Reduces energy use by creating a thermal break/barrier between metal roof & sheathing

- Dimensionally stable in hot weather – not brittle in cold

- Reduces roof noise from rain or sleet by up to 21 dB

- Easy to install – simply roll out over weather barrier or roof membrane

- Provides continuous air or water flow

- Durable and flexible structure is easy to cut and can be placed horizontally or vertically

The data reproduced in this document reflects our best knowledge at the time of the issue. It is subject to change arising from new research and development, as are the properties of the products described. We do not accept any liability for results obtained by using this information or the products mentioned.

Physical Properties

Polymer Properties

Nylon has excellent resistance to a variety of chemicals, alkaline, dilute acids, fuels and solvents found on construction sites. It is lightweight but also is very wear and abrasion-resistant. Nylon also has high tensile strength and a high heat distortion temperature.

The data reproduced in this document reflects our best knowledge at the time of the issue. It is subject to change arising from new research and development, as are the properties of the products described. We do not accept any liability for results obtained by using this information or the products mentioned.

Packaging

*Based on estimates...Customize roll sizes available upon special requet

The data reproduced in this document reflects our best knowledge at the time of the issue. It is subject to change arising from new research and development, as are the properties of the products described. We do not accept any liability for results obtained by using this information or the products mentioned.

Disclaimer: All information and product specifications provided in this document are accurate at the

time of publication. The provided information and product specifications may change at any time without notice and must not be relied upon unless expressly confirmed by a relevant member of

Global Plastic Sheeting, Inc upon request. No liability is undertaken for results obtained by usage

of the products and information.