Keeping Passengers Safe: Understanding FAR 25.853 in Airplane Interiors

Have you ever stopped to think about the fire safety measures in place within an airplane? Every detail, from the seat cushions to the overhead compartments, is meticulously regulated to ensure the highest level of passenger safety. Today, we'll delve into one such regulation: FAR 25.853.

What is FAR 25.853?

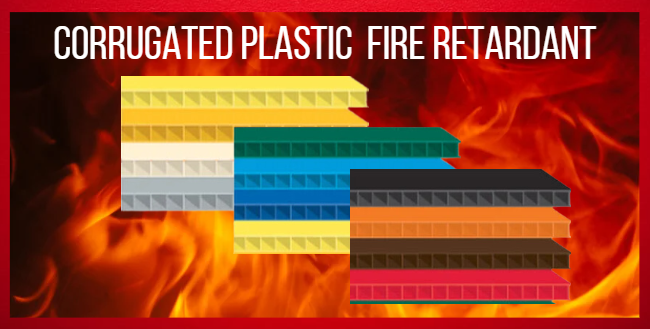

FAR 25.853 is a Federal Aviation Regulation (FAR) established by the Federal Aviation Administration (FAA) in the United States. This regulation focuses on the flammability standards for materials used in aircraft cabin and cargo compartments. In simpler terms, it dictates how easily these materials can catch fire and how they behave if a fire does occur.

Why is FAR 25.853 Important?

Imagine a scenario where a small fire breaks out on an airplane. FAR 25.853 helps prevent that minor incident from escalating into a catastrophic event. By ensuring cabin and cargo materials are flame retardant or slow the spread of flames, passengers and crew have precious time to react and evacuate safely.

What Does FAR 25.853 Regulate?

The regulation applies to a wide range of materials used in the airplane interior, including:

- Seat cushions and upholstery

- Wall and ceiling panels

- Flooring materials

- Cargo compartment liners

- Overhead bin materials

Meeting the Standards

Materials used in aircraft interiors must undergo rigorous testing to ensure they comply with FAR 25.853. These tests measure factors like ignition resistance, flame spread rate, and heat release. Materials that meet or exceed the established standards are then deemed suitable for use in airplane cabins and cargo compartments.

Beyond FAR 25.853

While FAR 25.853 is a crucial regulation, it's just one piece of the puzzle. Airplane manufacturers and airlines implement additional safety measures to further enhance fire safety. These include:

- Smoke detectors and fire alarm systems

- Onboard fire extinguishers

- Fire-resistant barriers between compartments

- Stringent crew training on fire emergency procedures

The Bottom Line

FAR 25.853 plays a vital role in ensuring the fire safety of airplane passengers and crew. By regulating the flammability of cabin and cargo materials, this regulation helps prevent small incidents from turning into major disasters. So, the next time you board a plane, take a moment to appreciate the extensive safety measures in place, including the unseen regulations like FAR 25.853, that contribute to a safe and comfortable flying experience.