Dive into Summer Fun: DIY Slip and Slide with 30 Mil White HDPE

Introduction: As the sun starts to shine brighter and temperatures rise, it's time to embrace the joys of summer and cool off with some outdoor fun. What better way to do that than with a homemade slip and slide? In this blog post, we'll show you how to create your own slip and slide using 30 mil white HDPE (High-Density Polyethylene) and explain why this particular material is ideal for the job.

Why 30 Mil White HDPE?

Before diving into the DIY process, let's talk about why 30 mil white HDPE is the perfect choice for your slip and slide project:

-

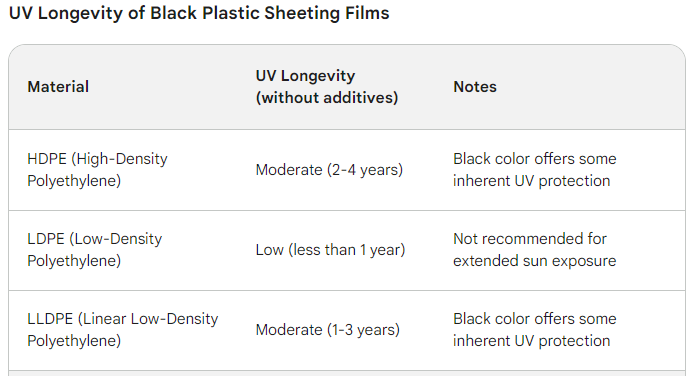

UV Protection: HDPE is known for its excellent UV resistance, making it durable and long-lasting even when exposed to the sun's rays for extended periods. This means your slip and slide will stay vibrant and intact throughout the summer season.

-

Thickness: The 30 mil thickness of the HDPE film provides added durability and strength, ensuring that your slip and slide can withstand the rigors of outdoor use without tearing or puncturing easily.

-

Slick Surface: HDPE has a naturally slick surface, which creates the perfect glide for sliding and ensures a smooth and enjoyable experience for all participants.

Now that we've covered why 30 mil white HDPE is the preferred material for your slip and slide, let's get into the DIY process.

Materials Needed:

- 30 mil white HDPE (available at hardware stores or online)

- Garden hose or sprinkler

- Tent stakes or heavy-duty staples

- Hammer or mallet

- Soap or dish detergent

- Water

Instructions:

-

Choose Your Location: Find a suitable outdoor area with a flat surface and enough space to lay out your slip and slide. Make sure there are no sharp objects or obstacles in the way.

-

Unroll the HDPE Film: Lay out the 30 mil white HDPE on the ground, ensuring that it is flat and smooth. You can cut the film to your desired length using scissors or a utility knife.

-

Secure the Edges: Use tent stakes or heavy-duty staples to secure the edges of the HDPE film to the ground, ensuring that it stays in place during use. Space the stakes or staples evenly along the perimeter of the slip and slide.

-

Add Water: Turn on the garden hose or sprinkler and wet the surface of the HDPE film thoroughly. This will create a slick surface for sliding and enhance the fun factor.

-

Apply Soap: Apply a generous amount of soap or dish detergent to the surface of the HDPE film, spreading it evenly with a sponge or brush. This will further lubricate the surface and increase the speed and smoothness of the slide.

-

Test It Out: Once everything is set up, it's time to test out your DIY slip and slide! Take a running start and dive onto the slick surface, enjoying the thrill of gliding across your backyard oasis.

-

Keep It Wet: To maintain optimal slipperiness, periodically reapply water and soap to the surface of the slip and slide as needed. This will ensure continuous fun for hours on end.

Why a Thinner Plastic Won't Last:

When it comes to creating a durable and practical slip and slide, opting for a thinner plastic material may seem like a cost-effective choice at first glance. However, thinner plastics simply don't hold up to the rigors of outdoor use and can lead to several drawbacks that compromise the overall experience. Here's why:

-

Tears and Rips: Thinner plastic materials are more susceptible to tears and rips, especially when subjected to repeated sliding and impact. This can quickly render the slip and slide unusable and require frequent repairs or replacements.

-

Flimsiness: Thinner plastics lack the structural integrity and stability needed to support the weight of sliding individuals, resulting in a flimsy and unstable surface. This can lead to uneven sliding, discomfort, and potential safety hazards.

-

Limited Durability: Thinner plastics are prone to degradation and deterioration over time, particularly when exposed to sunlight, water, and other outdoor elements. This means that your slip and slide may not last through an entire summer season, resulting in the need for frequent replacements.

-

Poor Performance: The slickness and smoothness of the slide surface are compromised with thinner plastics, leading to subpar sliding performance and reduced enjoyment for participants. This defeats the purpose of having a slip and slide in the first place.

In contrast, opting for a thicker plastic material like 30 mil white HDPE offers numerous advantages in terms of durability, performance, and longevity. Its superior strength, UV resistance, and slick surface make it the ideal choice for creating a slip and slide that can withstand the test of time and provide endless fun for summers to come. So, when it comes to your backyard waterpark adventures, investing in quality materials is key to ensuring a splashing good time for everyone involved.

Conclusion: With just a few simple materials and some creativity, you can create your own backyard waterpark with a DIY slip and slide made from 30 mil white HDPE. Not only is this project easy and affordable, but it also provides endless entertainment for family and friends during the hot summer months. So, gather your supplies, set up your slip and slide, and get ready to make a splash this summer